|

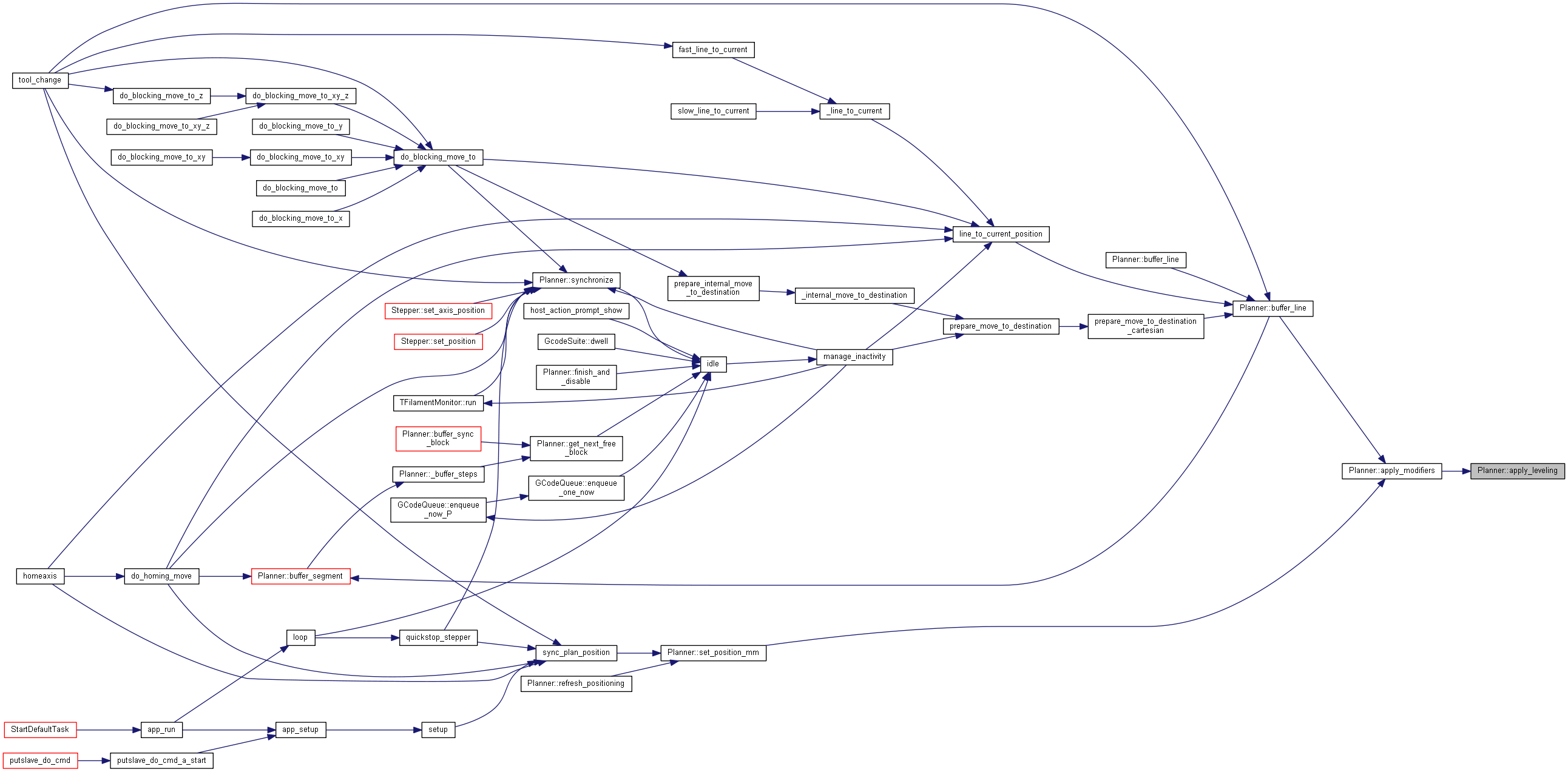

Prusa MINI Firmware overview

|

#include <planner.h>

|

| static void | reset_acceleration_rates () |

| |

| static void | refresh_positioning () |

| |

| static void | set_max_acceleration (const uint8_t axis, float targetValue) |

| |

| static void | set_max_feedrate (const uint8_t axis, float targetValue) |

| |

| static void | set_max_jerk (const AxisEnum axis, float targetValue) |

| |

| static void | check_axes_activity () |

| |

| static void | calculate_volumetric_multipliers () |

| |

| static FORCE_INLINE float | fade_scaling_factor_for_z (const float &) |

| |

| static FORCE_INLINE bool | leveling_active_at_z (const float &) |

| |

| static void | apply_leveling (xyz_pos_t &raw) |

| |

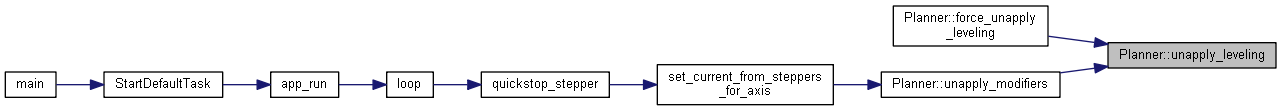

| static void | unapply_leveling (xyz_pos_t &raw) |

| |

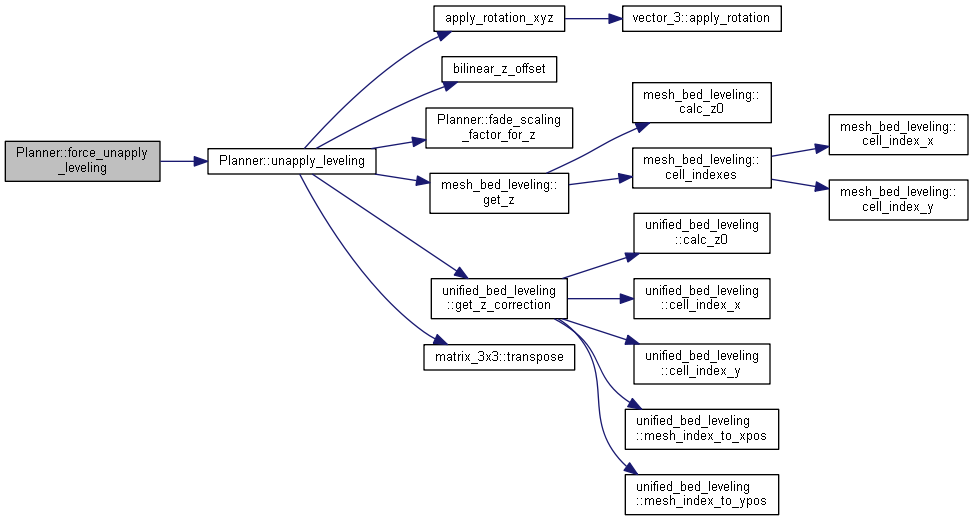

| static FORCE_INLINE void | force_unapply_leveling (xyz_pos_t &raw) |

| |

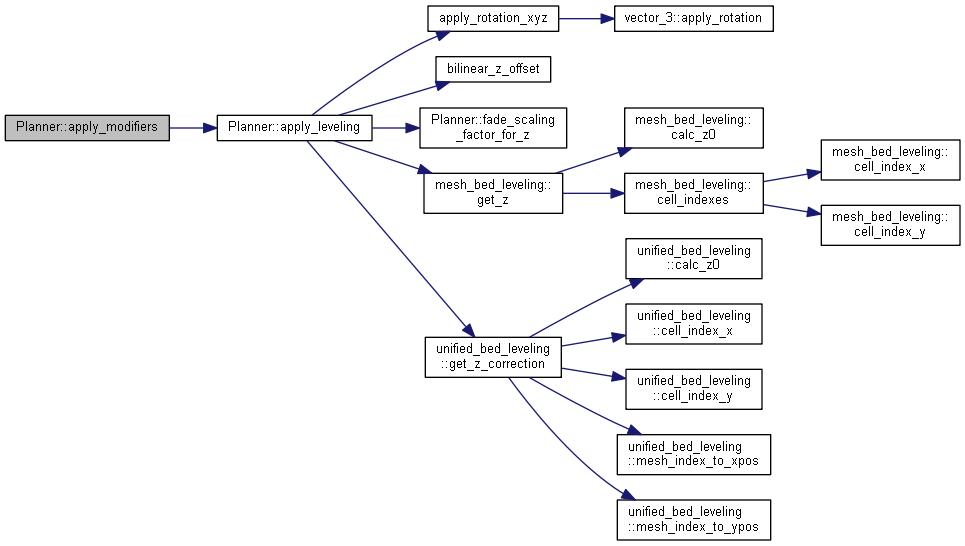

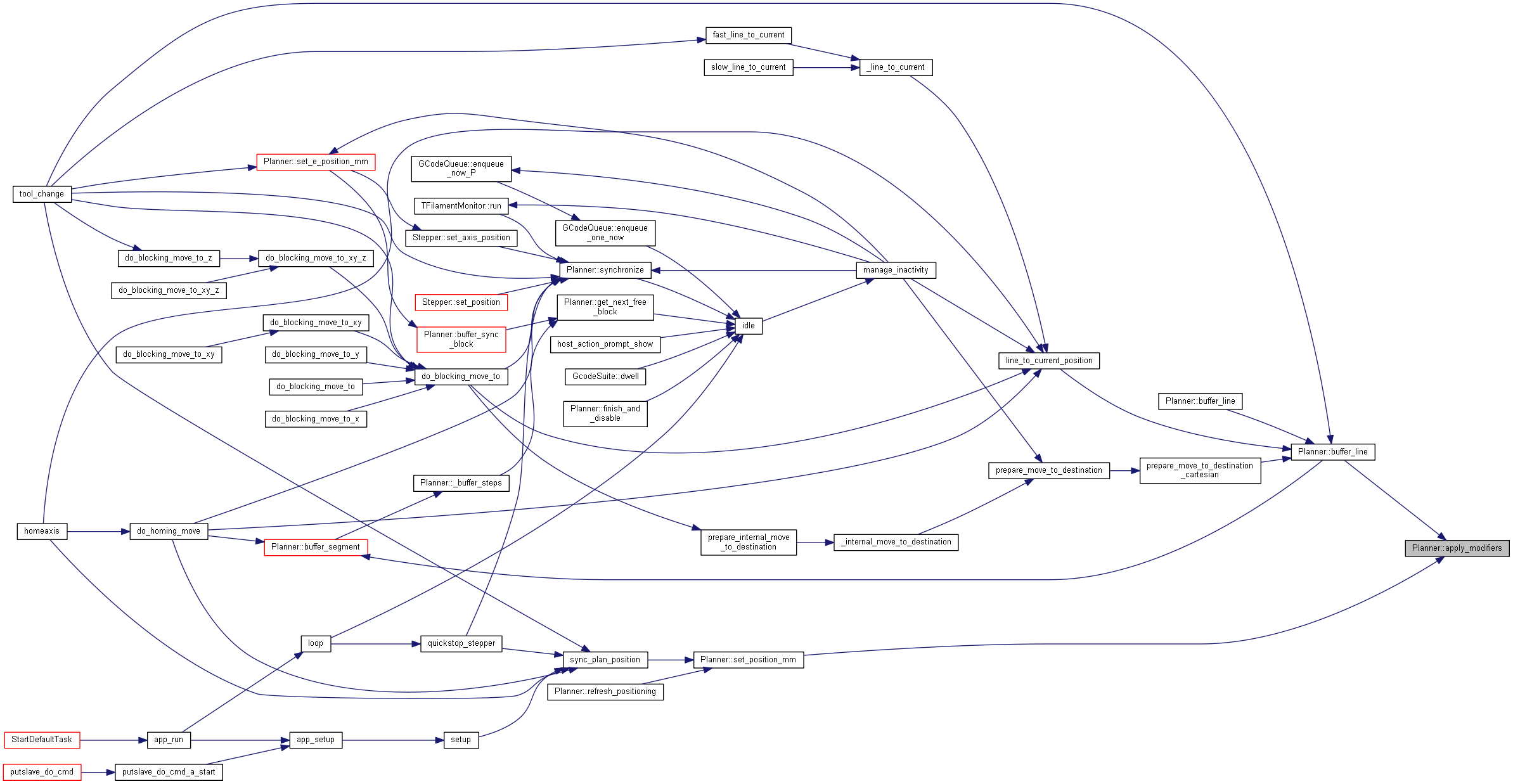

| static FORCE_INLINE void | apply_modifiers (xyze_pos_t &pos, bool leveling=false) |

| |

| static FORCE_INLINE void | unapply_modifiers (xyze_pos_t &pos, bool leveling=false) |

| |

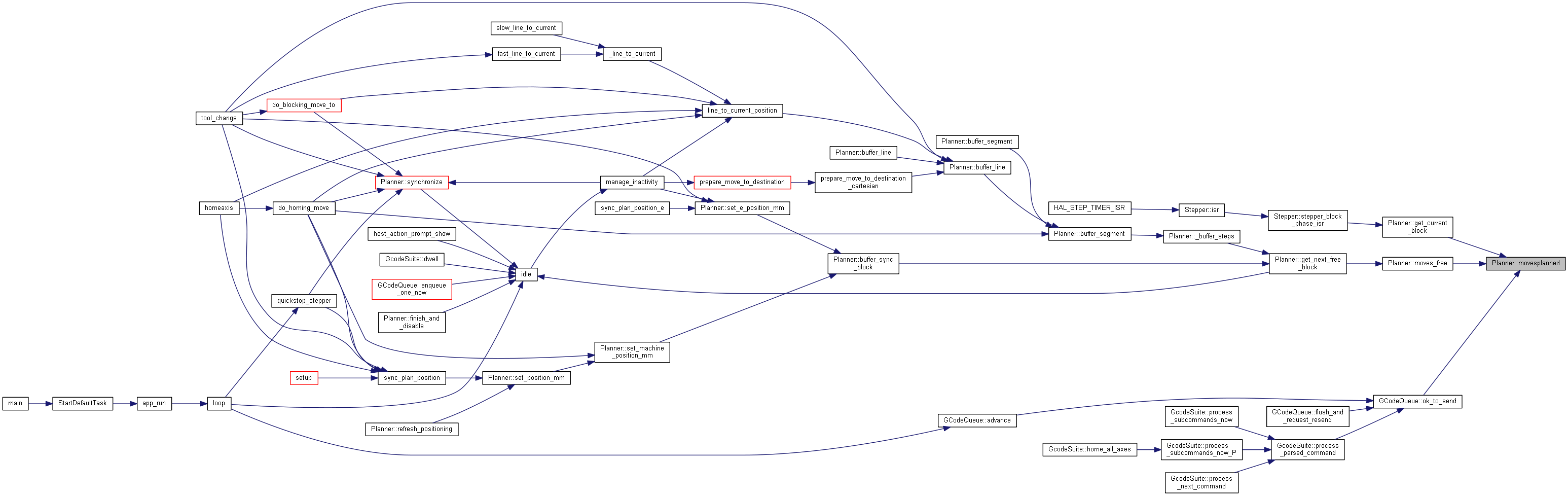

| static FORCE_INLINE uint8_t | movesplanned () |

| |

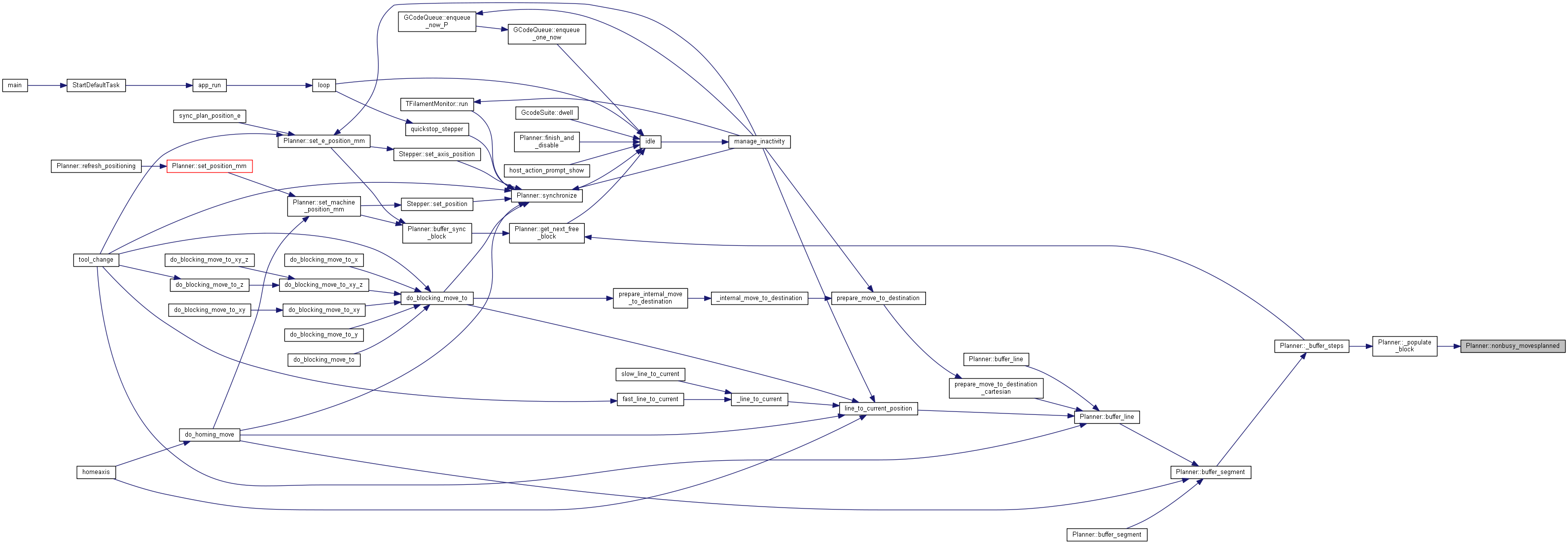

| static FORCE_INLINE uint8_t | nonbusy_movesplanned () |

| |

| static FORCE_INLINE void | clear_block_buffer () |

| |

| static FORCE_INLINE bool | is_full () |

| |

| static FORCE_INLINE uint8_t | moves_free () |

| |

| static FORCE_INLINE block_t * | get_next_free_block (uint8_t &next_buffer_head, const uint8_t count=1) |

| |

| static bool | _buffer_steps (const xyze_long_t &target, const xyze_pos_t &target_float, feedRate_t fr_mm_s, const uint8_t extruder, const float &millimeters=0.0) |

| |

| static bool | _populate_block (block_t *const block, bool split_move, const xyze_long_t &target, const xyze_pos_t &target_float, feedRate_t fr_mm_s, const uint8_t extruder, const float &millimeters=0.0) |

| |

| static void | buffer_sync_block () |

| |

| static bool | buffer_segment (const float &a, const float &b, const float &c, const float &e, const feedRate_t &fr_mm_s, const uint8_t extruder, const float &millimeters=0.0) |

| |

| static FORCE_INLINE bool | buffer_segment (abce_pos_t &abce, const feedRate_t &fr_mm_s, const uint8_t extruder, const float &millimeters=0.0) |

| |

| static bool | buffer_line (const float &rx, const float &ry, const float &rz, const float &e, const feedRate_t &fr_mm_s, const uint8_t extruder, const float millimeters=0.0) |

| |

| static FORCE_INLINE bool | buffer_line (const xyze_pos_t &cart, const feedRate_t &fr_mm_s, const uint8_t extruder, const float millimeters=0.0) |

| |

| static void | set_position_mm (const float &rx, const float &ry, const float &rz, const float &e) |

| |

| static FORCE_INLINE void | set_position_mm (const xyze_pos_t &cart) |

| |

| static void | set_e_position_mm (const float &e) |

| |

| static void | set_machine_position_mm (const float &a, const float &b, const float &c, const float &e) |

| |

| static FORCE_INLINE void | set_machine_position_mm (const abce_pos_t &abce) |

| |

| static float | get_axis_position_mm (const AxisEnum axis) |

| |

| static void | quick_stop () |

| |

| static void | endstop_triggered (const AxisEnum axis) |

| |

| static float | triggered_position_mm (const AxisEnum axis) |

| |

| static void | synchronize () |

| |

| static void | finish_and_disable () |

| |

| static void | tick () |

| |

| static FORCE_INLINE bool | has_blocks_queued () |

| |

| static block_t * | get_current_block () |

| |

| static FORCE_INLINE void | discard_current_block () |

| |

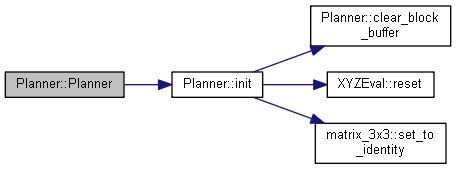

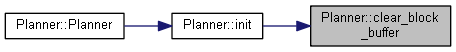

◆ Planner()

Instance Methods

Class and Instance Methods

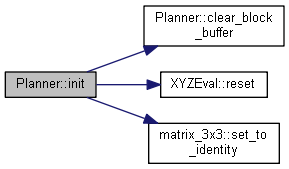

◆ init()

236 #if HAS_POSITION_FLOAT

240 position_cart.reset();

242 previous_speed.

reset();

243 previous_nominal_speed_sqr = 0;

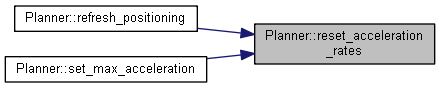

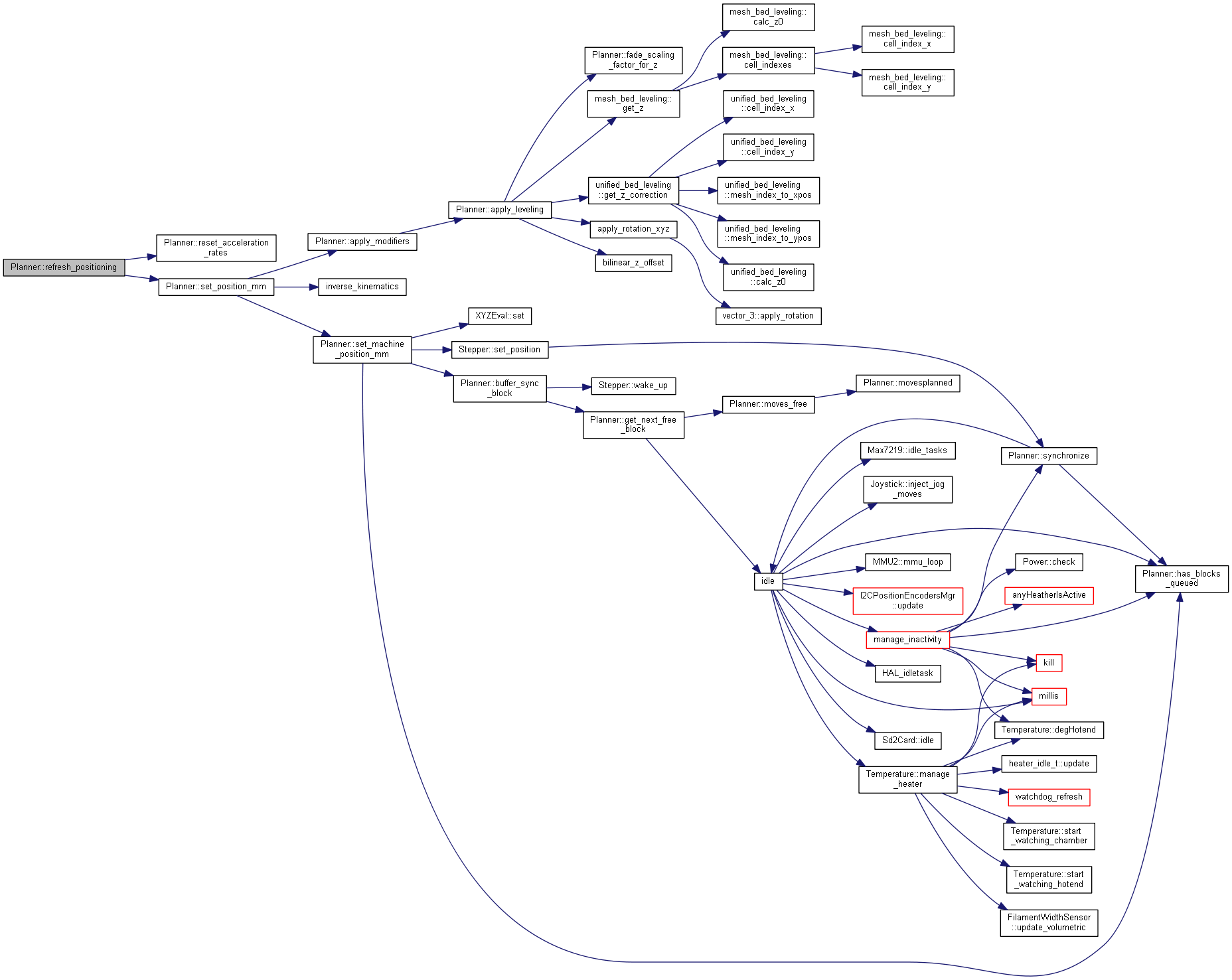

◆ reset_acceleration_rates()

| void Planner::reset_acceleration_rates |

( |

| ) |

|

|

static |

Static (class) Methods

2789 #if ENABLED(DISTINCT_E_FACTORS)

2790 #define AXIS_CONDITION (i < E_AXIS || i == E_AXIS_N(active_extruder))

2792 #define AXIS_CONDITION true

2794 uint32_t highest_rate = 1;

2799 cutoff_long = 4294967295UL / highest_rate;

2800 #if HAS_LINEAR_E_JERK

2801 recalculate_max_e_jerk();

◆ refresh_positioning()

| void Planner::refresh_positioning |

( |

| ) |

|

|

static |

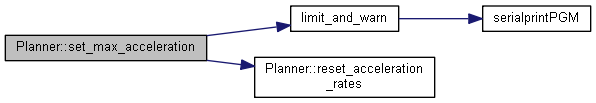

◆ set_max_acceleration()

2825 #if ENABLED(LIMITED_MAX_ACCEL_EDITING)

2826 #ifdef MAX_ACCEL_EDIT_VALUES

2827 constexpr

xyze_float_t max_accel_edit = MAX_ACCEL_EDIT_VALUES;

2828 const xyze_float_t &max_acc_edit_scaled = max_accel_edit;

2831 max_acc_edit_scaled = max_accel_edit * 2;

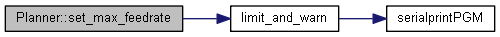

◆ set_max_feedrate()

2842 #if ENABLED(LIMITED_MAX_FR_EDITING)

2843 #ifdef MAX_FEEDRATE_EDIT_VALUES

2844 constexpr

xyze_float_t max_fr_edit = MAX_FEEDRATE_EDIT_VALUES;

2848 max_fr_edit_scaled = max_fr_edit * 2;

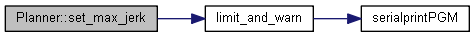

◆ set_max_jerk()

2856 #if HAS_CLASSIC_JERK

2857 #if ENABLED(LIMITED_JERK_EDITING)

2859 #ifdef MAX_JERK_EDIT_VALUES

2860 MAX_JERK_EDIT_VALUES

2862 { (DEFAULT_XJERK) * 2, (DEFAULT_YJERK) * 2,

2868 max_jerk[axis] = targetValue;

◆ check_axes_activity()

| void Planner::check_axes_activity |

( |

| ) |

|

|

static |

Maintain fans, paste extruder pressure,

1182 #if ANY(DISABLE_X, DISABLE_Y, DISABLE_Z, DISABLE_E)

1190 #if ENABLED(BARICUDA)

1201 #if FAN_COUNT > 0 || ENABLED(BARICUDA)

1210 #if ENABLED(BARICUDA)

1212 tail_valve_pressure = block->valve_pressure;

1215 tail_e_to_p_pressure = block->e_to_p_pressure;

1219 #if ANY(DISABLE_X, DISABLE_Y, DISABLE_Z, DISABLE_E)

1237 #if ENABLED(BARICUDA)

1250 #if ENABLED(DISABLE_X)

1253 #if ENABLED(DISABLE_Y)

1256 #if ENABLED(DISABLE_Z)

1259 #if ENABLED(DISABLE_E)

1268 #if FAN_KICKSTART_TIME > 0

1270 #define KICKSTART_FAN(f) \

1271 if (tail_fan_speed[f]) { \

1272 millis_t ms = millis(); \

1273 if (fan_kick_end[f] == 0) { \

1274 fan_kick_end[f] = ms + FAN_KICKSTART_TIME; \

1275 tail_fan_speed[f] = 255; \

1276 } else if (PENDING(ms, fan_kick_end[f])) \

1277 tail_fan_speed[f] = 255; \

1278 } else fan_kick_end[f] = 0

1280 #define KICKSTART_FAN(f) NOOP

1283 #if FAN_MIN_PWM != 0 || FAN_MAX_PWM != 255

1284 #define CALC_FAN_SPEED(f) (tail_fan_speed[f] ? map(tail_fan_speed[f], 1, 255, FAN_MIN_PWM, FAN_MAX_PWM) : 0)

1286 #define CALC_FAN_SPEED(f) tail_fan_speed[f]

1289 #if ENABLED(FAN_SOFT_PWM)

1290 #define _FAN_SET(F) thermalManager.soft_pwm_amount_fan[F] = CALC_FAN_SPEED(F);

1291 #elif ENABLED(FAST_PWM_FAN)

1292 #define _FAN_SET(F) set_pwm_duty(FAN##F##_PIN, CALC_FAN_SPEED(F));

1294 #define _FAN_SET(F) analogWrite(pin_t(FAN##F##_PIN), CALC_FAN_SPEED(F));

1296 #define FAN_SET(F) do{ KICKSTART_FAN(F); _FAN_SET(F); }while(0)

1308 #endif // FAN_COUNT > 0

1310 #if ENABLED(AUTOTEMP)

1314 #if ENABLED(BARICUDA)

◆ calculate_volumetric_multipliers()

| static void Planner::calculate_volumetric_multipliers |

( |

| ) |

|

|

static |

◆ fade_scaling_factor_for_z()

◆ leveling_active_at_z()

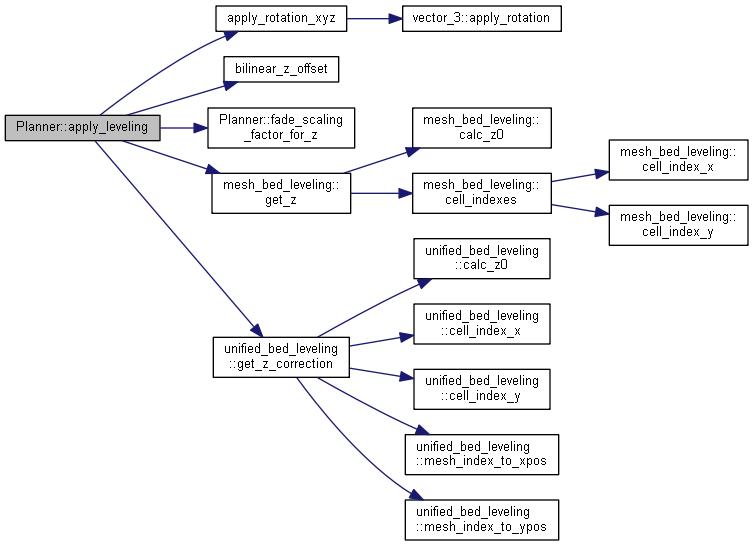

◆ apply_leveling()

Apply leveling to transform a cartesian position as it will be given to the planner and steppers.

rx, ry, rz - Cartesian positions in mm Leveled XYZ on completion

1392 #if ENABLED(ENABLE_LEVELING_FADE_HEIGHT)

1395 constexpr

float fade_scaling_factor = 1.0;

1399 #if ENABLED(MESH_BED_LEVELING)

1401 #

if ENABLED(ENABLE_LEVELING_FADE_HEIGHT)

1402 , fade_scaling_factor

1405 #elif ENABLED(AUTO_BED_LEVELING_UBL)

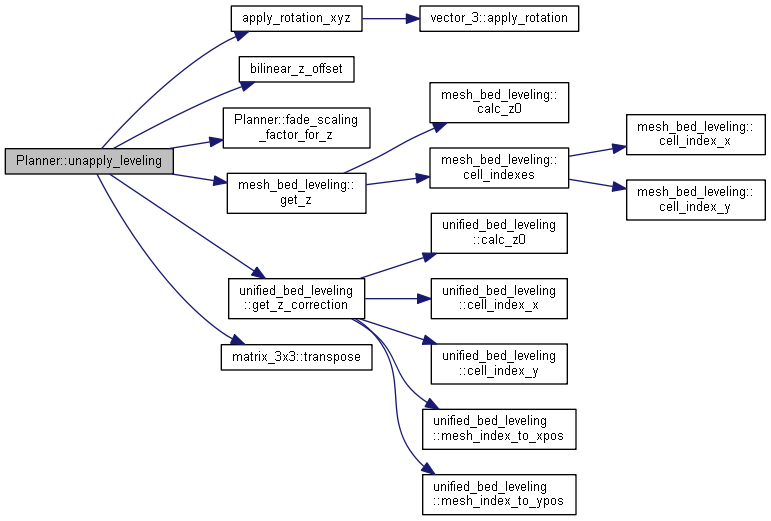

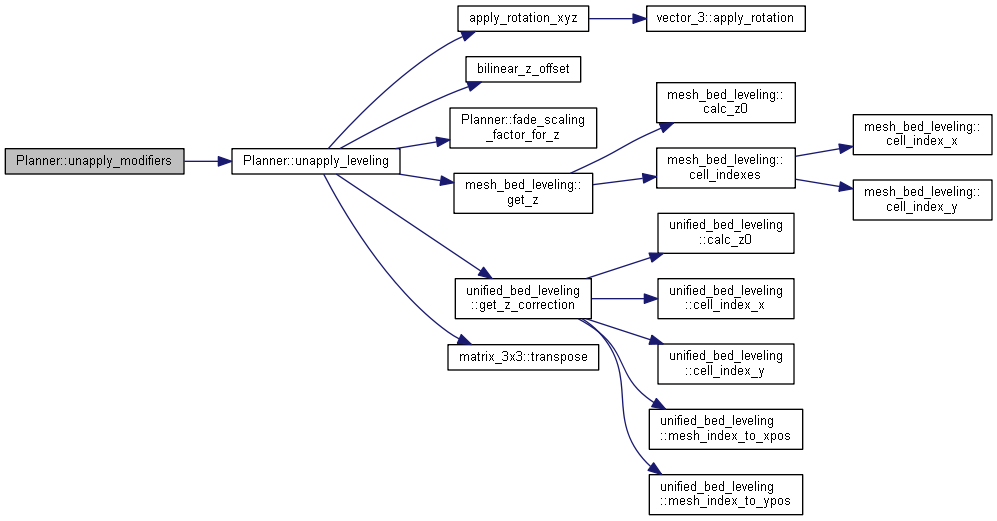

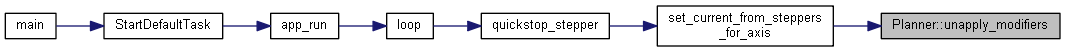

◆ unapply_leveling()

1429 #if ENABLED(ENABLE_LEVELING_FADE_HEIGHT)

1432 constexpr

float fade_scaling_factor = 1.0;

1436 #if ENABLED(MESH_BED_LEVELING)

1438 #

if ENABLED(ENABLE_LEVELING_FADE_HEIGHT)

1439 , fade_scaling_factor

1442 #elif ENABLED(AUTO_BED_LEVELING_UBL)

1452 #if ENABLED(SKEW_CORRECTION)

◆ force_unapply_leveling()

◆ apply_modifiers()

509 #if ENABLED(SKEW_CORRECTION)

515 #if ENABLED(FWRETRACT)

◆ unapply_modifiers()

530 #if ENABLED(FWRETRACT)

531 unapply_retract(pos);

536 #if ENABLED(SKEW_CORRECTION)

◆ movesplanned()

◆ nonbusy_movesplanned()

◆ clear_block_buffer()

◆ is_full()

◆ moves_free()

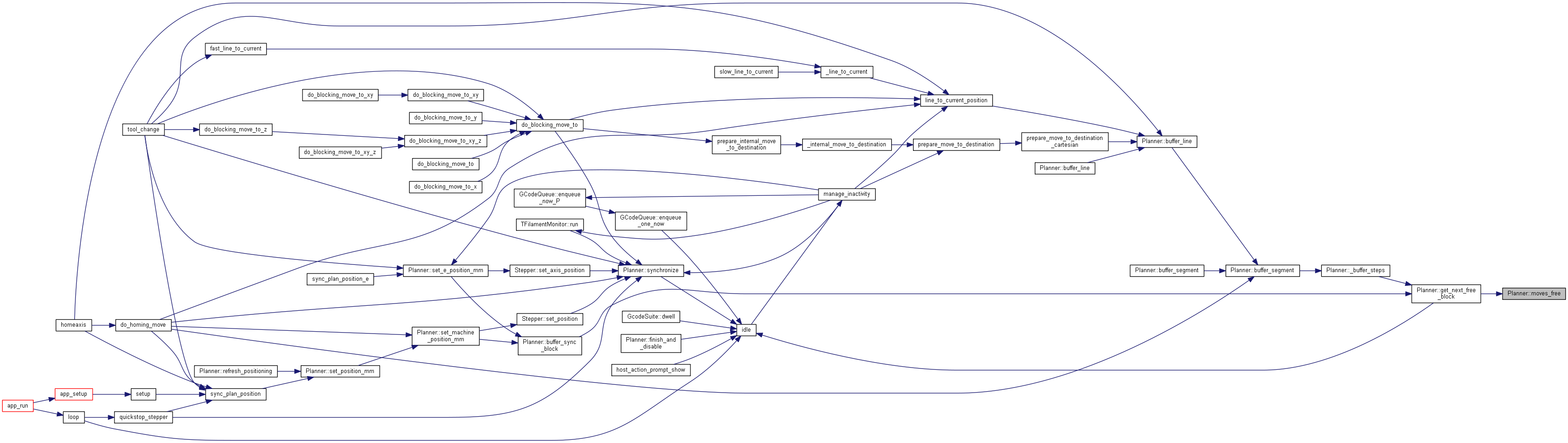

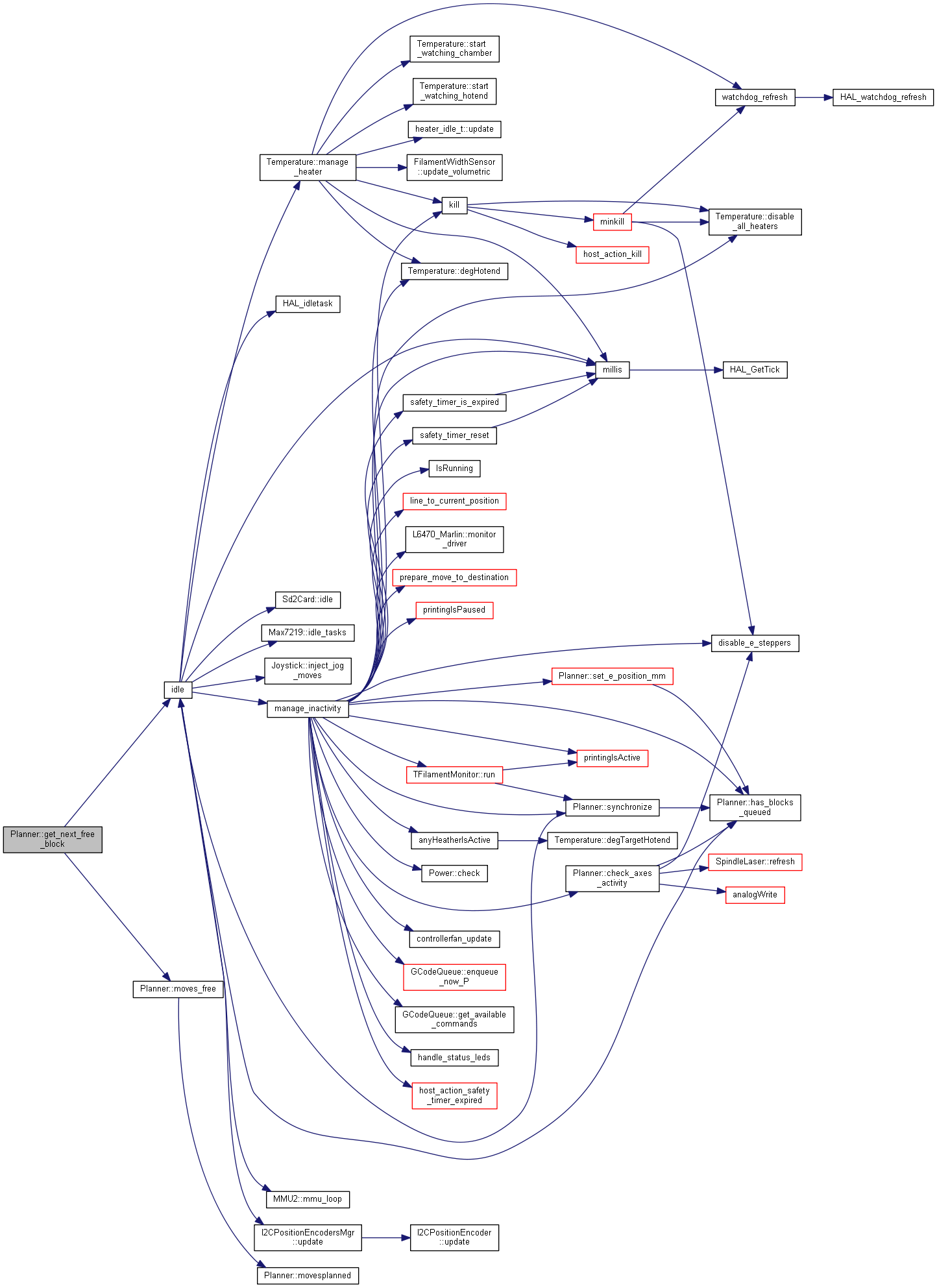

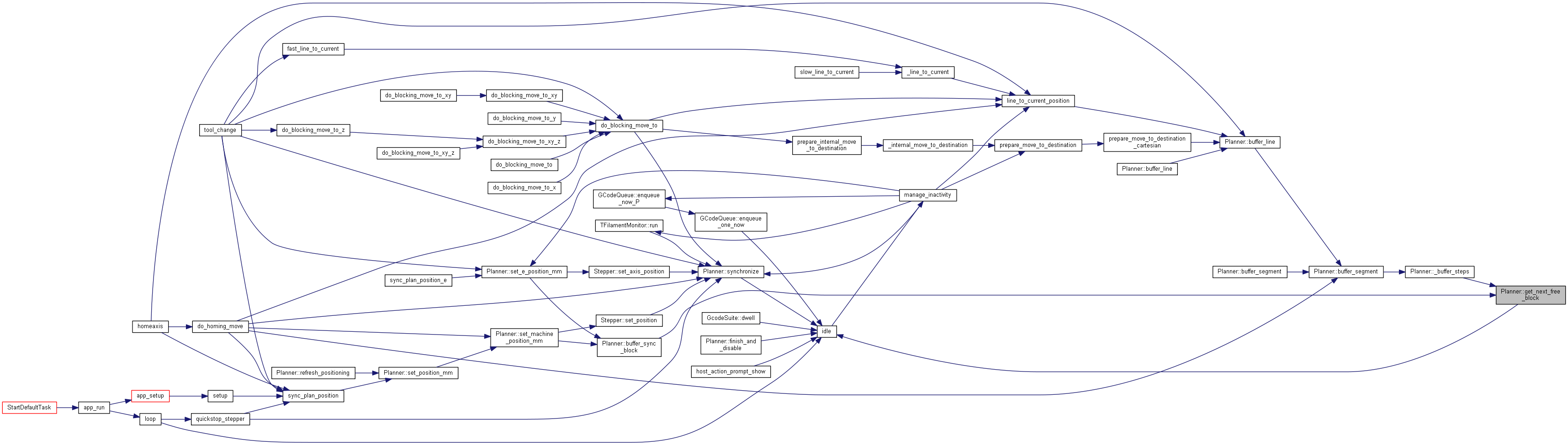

◆ get_next_free_block()

Planner::get_next_free_block

- Get the next head indices (passed by reference)

- Wait for the number of spaces to open up in the planner

- Return the first head block

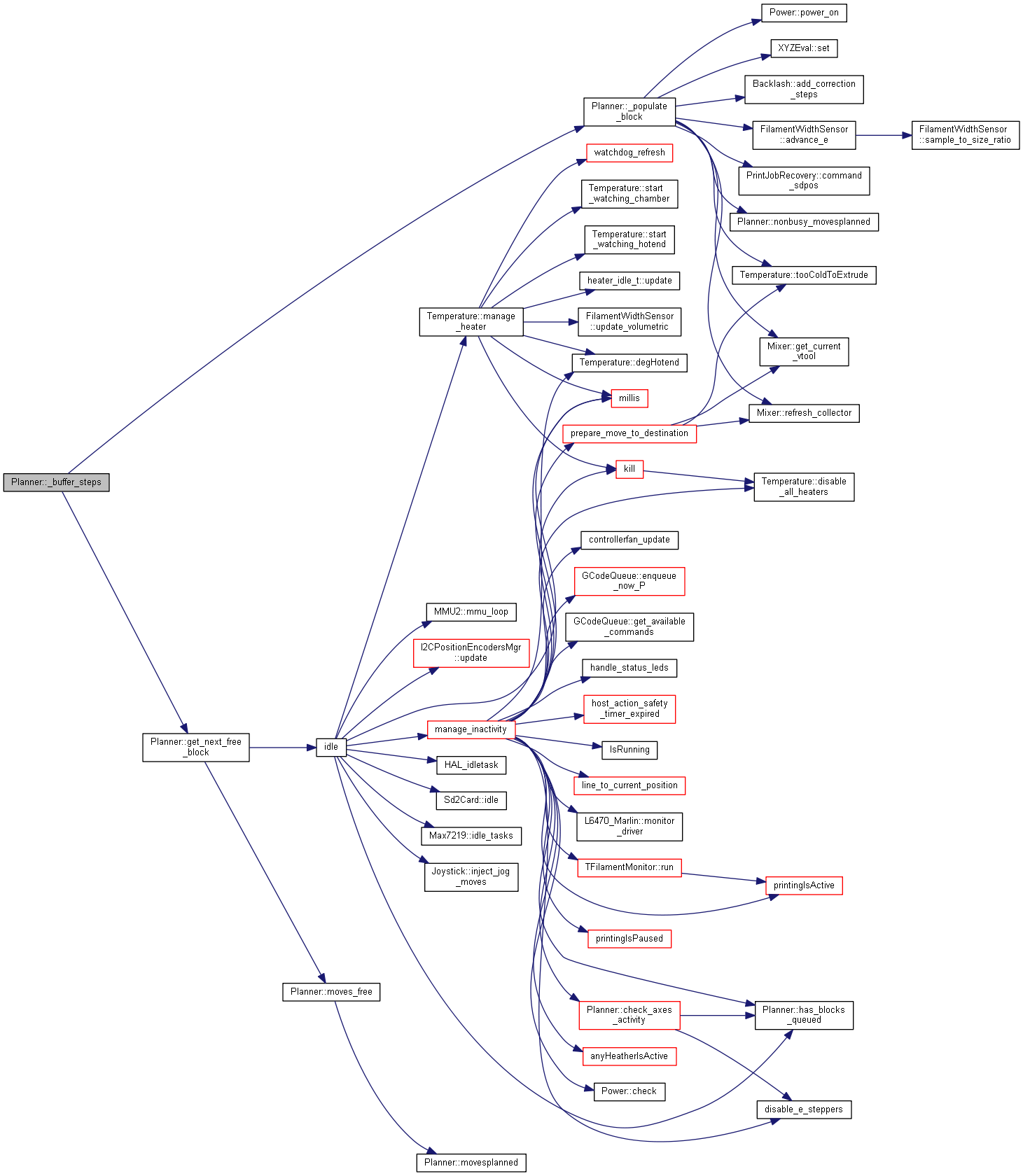

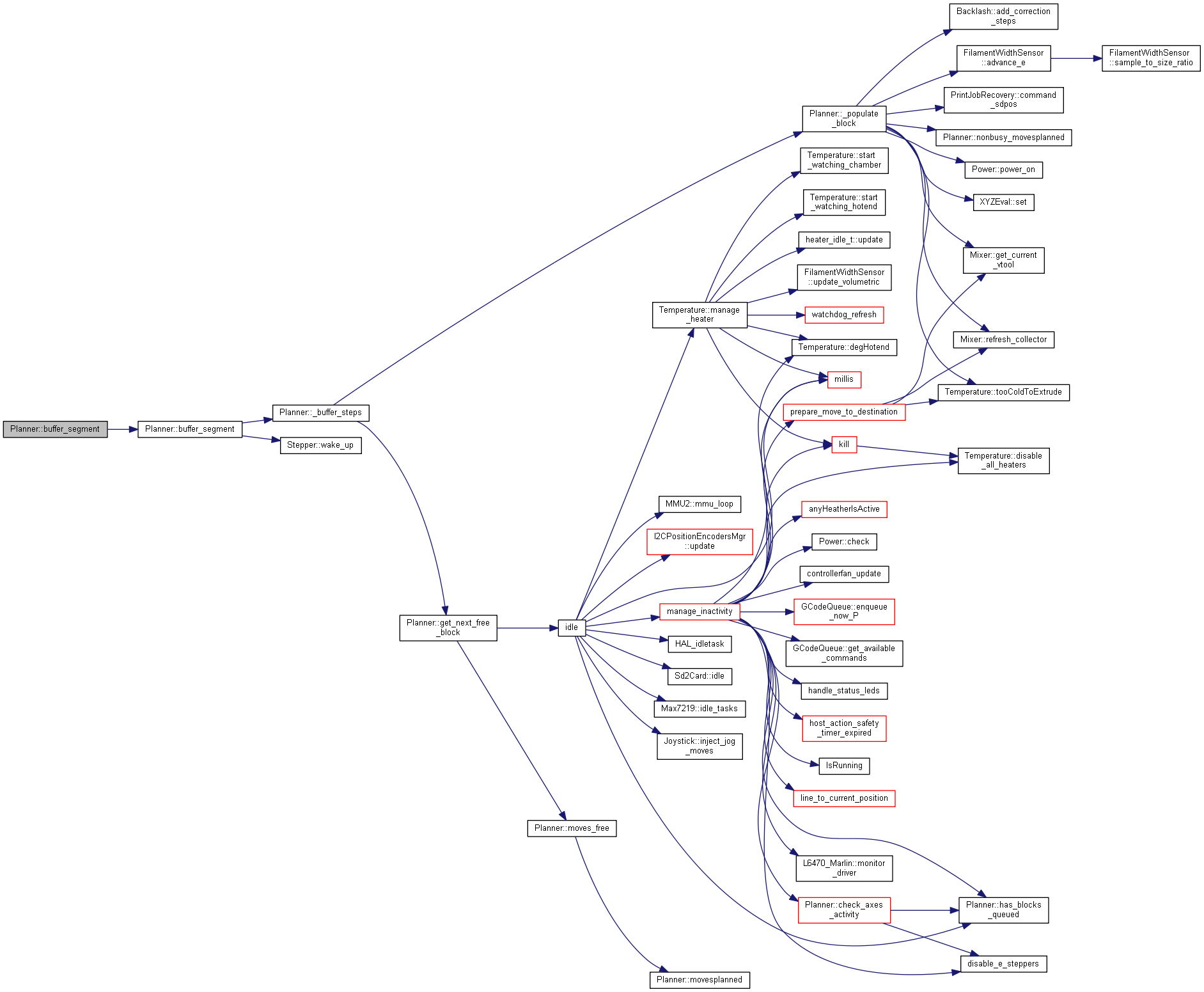

◆ _buffer_steps()

Planner::_buffer_steps

Add a new linear movement to the buffer (in terms of steps).

target - target position in steps units fr_mm_s - (target) speed of the move extruder - target extruder millimeters - the length of the movement, if known

Returns true if movement was buffered, false otherwise

Planner::_buffer_steps

Add a new linear movement to the planner queue (in terms of steps).

target - target position in steps units target_float - target position in direct (mm, degrees) units. optional fr_mm_s - (target) speed of the move extruder - target extruder millimeters - the length of the movement, if known

Returns true if movement was properly queued, false otherwise

1603 , fr_mm_s, extruder, millimeters

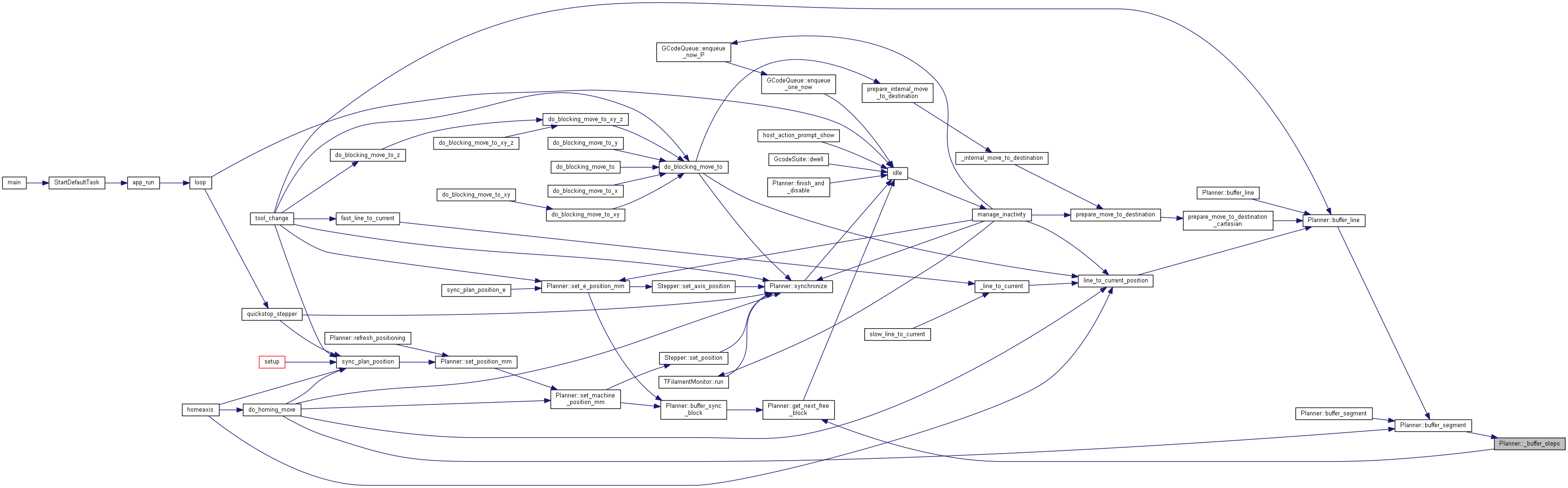

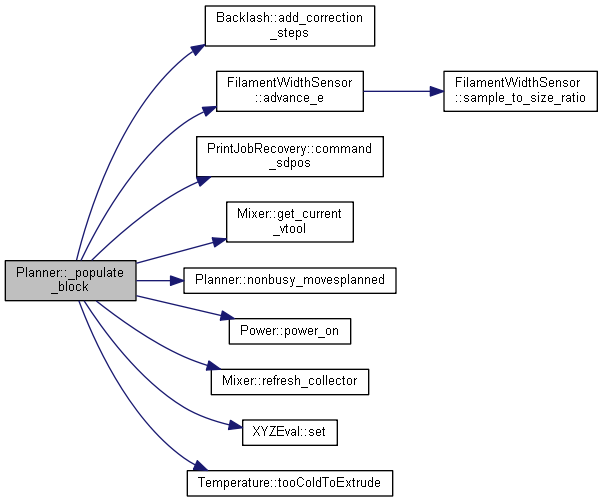

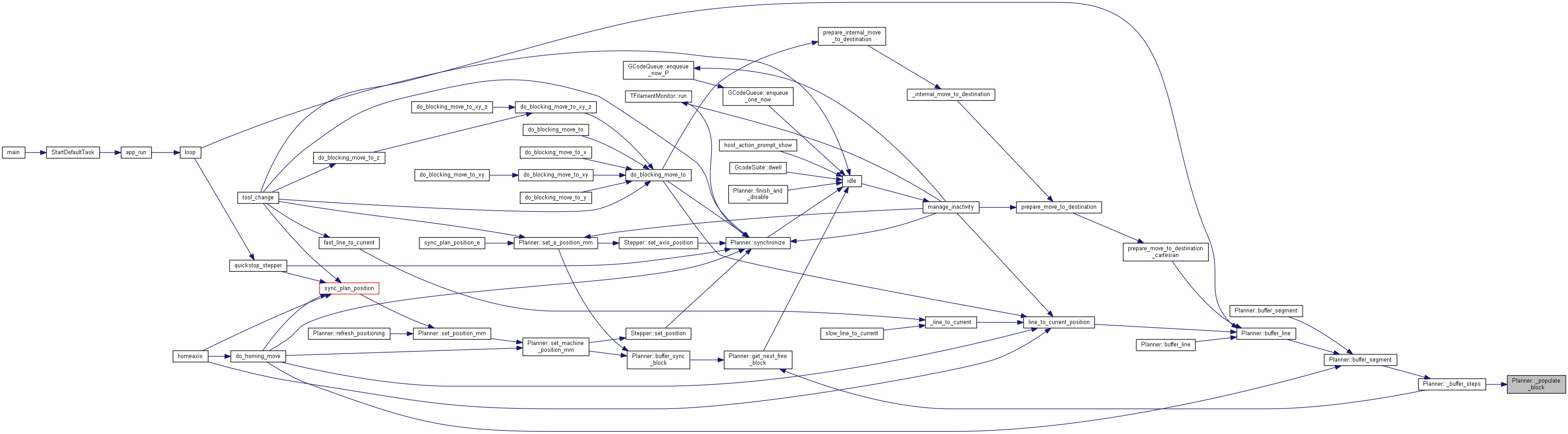

◆ _populate_block()

Planner::_populate_block

Fills a new linear movement in the block (in terms of steps).

target - target position in steps units fr_mm_s - (target) speed of the move extruder - target extruder millimeters - the length of the movement, if known

Returns true is movement is acceptable, false otherwise

Planner::_populate_block

Fills a new linear movement in the block (in terms of steps).

target - target position in steps units fr_mm_s - (target) speed of the move extruder - target extruder

Returns true is movement is acceptable, false otherwise

This part of the code calculates the total length of the movement. For cartesian bots, the X_AXIS is the real X movement and same for Y_AXIS. But for corexy bots, that is not true. The "X_AXIS" and "Y_AXIS" motors (that should be named to A_AXIS and B_AXIS) cannot be used for X and Y length, because A=X+Y and B=X-Y. So we need to create other 2 "AXIS", named X_HEAD and Y_HEAD, meaning the real displacement of the Head. Having the real displacement of the head, we can calculate the total movement length and apply the desired speed.

At this point at least one of the axes has more steps than MIN_STEPS_PER_SEGMENT, ensuring the segment won't get dropped as zero-length. It's important to not apply corrections to blocks that would get dropped!

A correction function is permitted to add steps to an axis, it should never remove steps!

1652 const int32_t da = target.

a - position.

a,

1653 db = target.

b - position.

b,

1654 dc = target.

c - position.

c;

1657 int32_t de = target.

e - position.

e;

1659 constexpr int32_t de = 0;

1673 #if EITHER(PREVENT_COLD_EXTRUSION, PREVENT_LENGTHY_EXTRUDE)

1675 #if ENABLED(PREVENT_COLD_EXTRUSION)

1677 position.

e = target.

e;

1678 #if HAS_POSITION_FLOAT

1684 #endif // PREVENT_COLD_EXTRUSION

1685 #if ENABLED(PREVENT_LENGTHY_EXTRUDE)

1686 const float e_steps =

ABS(de * e_factor[extruder]);

1688 if (e_steps > max_e_steps) {

1689 #if ENABLED(MIXING_EXTRUDER)

1690 bool ignore_e =

false;

1691 float collector[MIXING_STEPPERS];

1694 if (e_steps * collector[e] > max_e_steps) { ignore_e =

true;

break; }

1696 constexpr

bool ignore_e =

true;

1699 position.

e = target.

e;

1700 #if HAS_POSITION_FLOAT

1707 #endif // PREVENT_LENGTHY_EXTRUDE

1709 #endif // PREVENT_COLD_EXTRUSION || PREVENT_LENGTHY_EXTRUDE

1718 if (CORESIGN(da - db) < 0)

SBI(dm,

B_AXIS);

1724 if (CORESIGN(da - dc) < 0)

SBI(dm,

C_AXIS);

1730 if (CORESIGN(db - dc) < 0)

SBI(dm,

C_AXIS);

1739 const float esteps_float = de * e_factor[extruder];

1740 const uint32_t esteps =

ABS(esteps_float) + 0.5f;

1742 constexpr uint32_t esteps = 0;

1822 sq(delta_mm.head.x) +

sq(delta_mm.head.y) +

sq(delta_mm.z)

1824 sq(delta_mm.head.x) +

sq(delta_mm.y) +

sq(delta_mm.head.z)

1826 sq(delta_mm.x) +

sq(delta_mm.head.y) +

sq(delta_mm.head.z)

1828 sq(delta_mm.x) +

sq(delta_mm.y) +

sq(delta_mm.z)

1841 #if ENABLED(BACKLASH_COMPENSATION)

1855 #if ENABLED(MIXING_EXTRUDER)

1867 #if ENABLED(BARICUDA)

1876 #if ENABLED(AUTO_POWER_CONTROL)

1887 #if DISABLED(Z_LATE_ENABLE)

1905 #if DISABLED(Z_LATE_ENABLE)

1913 #if ENABLED(AUTO_POWER_CONTROL)

1917 #if ENABLED(DISABLE_INACTIVE_EXTRUDER) // Enable only the selected extruder

1919 #define DISABLE_IDLE_E(N) if (!g_uc_extruder_last_move[N]) disable_E##N();

1922 if (g_uc_extruder_last_move[

i] > 0) g_uc_extruder_last_move[

i]--;

1936 #endif // EXTRUDERS > 5

1937 #endif // EXTRUDERS > 4

1938 #endif // EXTRUDERS > 3

1939 #endif // EXTRUDERS > 2

1940 #endif // EXTRUDERS > 1

1943 #if HAS_DUPLICATION_MODE

1961 #endif // EXTRUDERS > 5

1962 #endif // EXTRUDERS > 4

1963 #endif // EXTRUDERS > 3

1964 #endif // EXTRUDERS > 2

2020 #endif // EXTRUDERS > 5

2021 #endif // EXTRUDERS > 4

2022 #endif // EXTRUDERS > 3

2023 #endif // EXTRUDERS > 2

2024 #endif // EXTRUDERS > 1

2042 const float inverse_millimeters = 1.0f / block->

millimeters;

2046 float inverse_secs = fr_mm_s * inverse_millimeters;

2052 #if EITHER(SLOWDOWN, ULTRA_LCD) || defined(XY_FREQUENCY_LIMIT)

2054 uint32_t segment_time_us =

LROUND(1000000.0f / inverse_secs);

2057 #if ENABLED(SLOWDOWN)

2062 inverse_secs = 1000000.0f / nst;

2063 #if defined(XY_FREQUENCY_LIMIT) || HAS_SPI_LCD

2064 segment_time_us = nst;

2075 block_buffer_runtime_us += segment_time_us;

2076 block->segment_time_us = segment_time_us;

2084 #if ENABLED(FILAMENT_WIDTH_SENSOR)

2085 if (extruder == FILAMENT_SENSOR_EXTRUDER_NUM)

2091 float speed_factor = 1.0f;

2093 #if BOTH(MIXING_EXTRUDER, RETRACT_SYNC_MIXING)

2096 float delta_mm_i = 0;

2098 delta_mm_i = delta_mm.e / MIXING_STEPPERS;

2100 delta_mm_i = delta_mm.e;

2102 const float delta_mm_i = delta_mm[

i];

2104 const feedRate_t cs =

ABS(current_speed[

i] = delta_mm_i * inverse_secs);

2105 #if ENABLED(DISTINCT_E_FACTORS)

2112 #ifdef XY_FREQUENCY_LIMIT

2115 const unsigned char direction_change = block->

direction_bits ^ old_direction_bits;

2117 segment_time_us =

LROUND((

float)segment_time_us / speed_factor);

2119 uint32_t xs0 = axis_segment_time_us[0].x,

2120 xs1 = axis_segment_time_us[1].x,

2121 xs2 = axis_segment_time_us[2].x,

2122 ys0 = axis_segment_time_us[0].y,

2123 ys1 = axis_segment_time_us[1].y,

2124 ys2 = axis_segment_time_us[2].y;

2127 xs2 = axis_segment_time_us[2].x = xs1;

2128 xs1 = axis_segment_time_us[1].x = xs0;

2131 xs0 = axis_segment_time_us[0].x = xs0 + segment_time_us;

2134 ys2 = axis_segment_time_us[2].y = axis_segment_time_us[1].y;

2135 ys1 = axis_segment_time_us[1].y = axis_segment_time_us[0].y;

2138 ys0 = axis_segment_time_us[0].y = ys0 + segment_time_us;

2140 const uint32_t max_x_segment_time =

_MAX(xs0, xs1, xs2),

2141 max_y_segment_time =

_MAX(ys0, ys1, ys2),

2142 min_xy_segment_time =

_MIN(max_x_segment_time, max_y_segment_time);

2143 if (min_xy_segment_time < MAX_FREQ_TIME_US) {

2144 const float low_sf = speed_factor * min_xy_segment_time / (MAX_FREQ_TIME_US);

2145 NOMORE(speed_factor, low_sf);

2147 #endif // XY_FREQUENCY_LIMIT

2150 if (speed_factor < 1.0f) {

2151 current_speed *= speed_factor;

2162 #if ENABLED(LIN_ADVANCE)

2163 block->use_advance_lead =

false;

2167 #define LIMIT_ACCEL_LONG(AXIS,INDX) do{ \

2168 if (block->steps[AXIS] && max_acceleration_steps_per_s2[AXIS+INDX] < accel) { \

2169 const uint32_t comp = max_acceleration_steps_per_s2[AXIS+INDX] * block->step_event_count; \

2170 if (accel * block->steps[AXIS] > comp) accel = comp / block->steps[AXIS]; \

2174 #define LIMIT_ACCEL_FLOAT(AXIS,INDX) do{ \

2175 if (block->steps[AXIS] && max_acceleration_steps_per_s2[AXIS+INDX] < accel) { \

2176 const float comp = (float)max_acceleration_steps_per_s2[AXIS+INDX] * (float)block->step_event_count; \

2177 if ((float)accel * (float)block->steps[AXIS] > comp) accel = comp / (float)block->steps[AXIS]; \

2184 #if ENABLED(LIN_ADVANCE)

2186 #if DISABLED(CLASSIC_JERK)

2187 #if ENABLED(DISTINCT_E_FACTORS)

2188 #define MAX_E_JERK max_e_jerk[extruder]

2190 #define MAX_E_JERK max_e_jerk

2193 #define MAX_E_JERK max_jerk.e

2206 block->use_advance_lead = esteps

2210 if (block->use_advance_lead) {

2223 if (block->e_D_ratio > 3.0f)

2224 block->use_advance_lead =

false;

2226 const uint32_t max_accel_steps_per_s2 = MAX_E_JERK / (extruder_advance_K[

active_extruder] * block->e_D_ratio) * steps_per_mm;

2227 #if ENABLED(LA_DEBUG)

2228 if (accel > max_accel_steps_per_s2)

SERIAL_ECHOLNPGM(

"Acceleration limited.");

2230 NOMORE(accel, max_accel_steps_per_s2);

2235 #if ENABLED(DISTINCT_E_FACTORS)

2236 #define ACCEL_IDX extruder

2257 #if DISABLED(S_CURVE_ACCELERATION)

2260 #if ENABLED(LIN_ADVANCE)

2261 if (block->use_advance_lead) {

2263 #if ENABLED(LA_DEBUG)

2266 if (block->advance_speed < 200)

2272 float vmax_junction_sqr;

2274 #if DISABLED(CLASSIC_JERK)

2313 #if IS_KINEMATIC && DISABLED(CLASSIC_JERK)

2316 { delta_mm.

x, delta_mm.y, delta_mm.z, delta_mm.e }

2319 unit_vec *= inverse_millimeters;

2321 #if IS_CORE && DISABLED(CLASSIC_JERK)

2327 normalize_junction_vector(unit_vec);

2331 if (moves_queued && !

UNEAR_ZERO(previous_nominal_speed_sqr)) {

2334 float junction_cos_theta = (-prev_unit_vec.

x * unit_vec.

x) + (-prev_unit_vec.

y * unit_vec.

y)

2335 + (-prev_unit_vec.

z * unit_vec.

z) + (-prev_unit_vec.

e * unit_vec.

e);

2338 if (junction_cos_theta > 0.999999f) {

2343 NOLESS(junction_cos_theta, -0.999999f);

2346 xyze_float_t junction_unit_vec = unit_vec - prev_unit_vec;

2347 normalize_junction_vector(junction_unit_vec);

2349 const float junction_acceleration = limit_value_by_axis_maximum(block->

acceleration, junction_unit_vec),

2350 sin_theta_d2 =

SQRT(0.5f * (1.0f - junction_cos_theta));

2352 vmax_junction_sqr = (junction_acceleration * junction_deviation_mm * sin_theta_d2) / (1.0f - sin_theta_d2);

2356 const float junction_theta = (

RADIANS(-40) *

sq(junction_cos_theta) -

RADIANS(50)) * junction_cos_theta +

RADIANS(90) - 0.18f;

2359 if (junction_theta >

RADIANS(135)) {

2360 const float limit_sqr = block->

millimeters / (

RADIANS(180) - junction_theta) * junction_acceleration;

2361 NOMORE(vmax_junction_sqr, limit_sqr);

2370 vmax_junction_sqr = 0;

2372 prev_unit_vec = unit_vec;

2376 #ifdef USE_CACHED_SQRT

2377 #define CACHED_SQRT(N, V) \

2378 static float saved_V, N; \

2379 if (V != saved_V) { N = SQRT(V); saved_V = V; }

2381 #define CACHED_SQRT(N, V) const float N = SQRT(V)

2384 #if HAS_CLASSIC_JERK

2393 static float previous_safe_speed;

2396 float safe_speed = nominal_speed;

2399 #if HAS_LINEAR_E_JERK

2405 const float jerk =

ABS(current_speed[

i]),

2409 const float mjerk = nominal_speed * maxj;

2410 if (jerk * safe_speed > mjerk) safe_speed = mjerk / jerk;

2413 safe_speed *= maxj / jerk;

2419 float vmax_junction;

2420 if (moves_queued && !

UNEAR_ZERO(previous_nominal_speed_sqr)) {

2431 CACHED_SQRT(previous_nominal_speed, previous_nominal_speed_sqr);

2433 vmax_junction =

_MIN(nominal_speed, previous_nominal_speed);

2436 const float smaller_speed_factor = vmax_junction / previous_nominal_speed;

2437 #if HAS_LINEAR_E_JERK

2444 float v_exit = previous_speed[axis] * smaller_speed_factor,

2445 v_entry = current_speed[axis];

2448 v_entry *= v_factor;

2452 const float jerk = (v_exit > v_entry)

2454 ( (v_entry > 0 || v_exit < 0) ? (v_exit - v_entry) :

_MAX(v_exit, -v_entry) )

2456 ( (v_entry < 0 || v_exit > 0) ? (v_entry - v_exit) :

_MAX(-v_exit, v_entry) );

2458 if (jerk > max_jerk[axis]) {

2459 v_factor *= max_jerk[axis] / jerk;

2463 if (limited) vmax_junction *= v_factor;

2466 const float vmax_junction_threshold = vmax_junction * 0.99f;

2467 if (previous_safe_speed > vmax_junction_threshold && safe_speed > vmax_junction_threshold)

2468 vmax_junction = safe_speed;

2471 vmax_junction = safe_speed;

2473 previous_safe_speed = safe_speed;

2475 #if DISABLED(CLASSIC_JERK)

2476 vmax_junction_sqr =

_MIN(vmax_junction_sqr,

sq(vmax_junction));

2478 vmax_junction_sqr =

sq(vmax_junction);

2481 #endif // Classic Jerk Limiting

2504 previous_speed = current_speed;

2509 #if HAS_POSITION_FLOAT

2513 #if ENABLED(GRADIENT_MIX)

2514 mixer.gradient_control(target_float.

z);

2517 #if ENABLED(POWER_LOSS_RECOVERY)

◆ buffer_sync_block()

| void Planner::buffer_sync_block |

( |

| ) |

|

|

static |

◆ buffer_segment() [1/2]

Planner::buffer_segment

Add a new linear movement to the buffer in axis units.

Leveling and kinematics should be applied ahead of calling this.

a,b,c,e - target positions in mm and/or degrees fr_mm_s - (target) speed of the move extruder - target extruder millimeters - the length of the movement, if known

2579 #if ENABLED(DISTINCT_E_FACTORS)

2582 last_extruder = extruder;

2595 #if HAS_POSITION_FLOAT

2601 position.

e = target.

e;

2602 #if HAS_POSITION_FLOAT

2644 , fr_mm_s, extruder, millimeters

◆ buffer_segment() [2/2]

661 , fr_mm_s, extruder, millimeters);

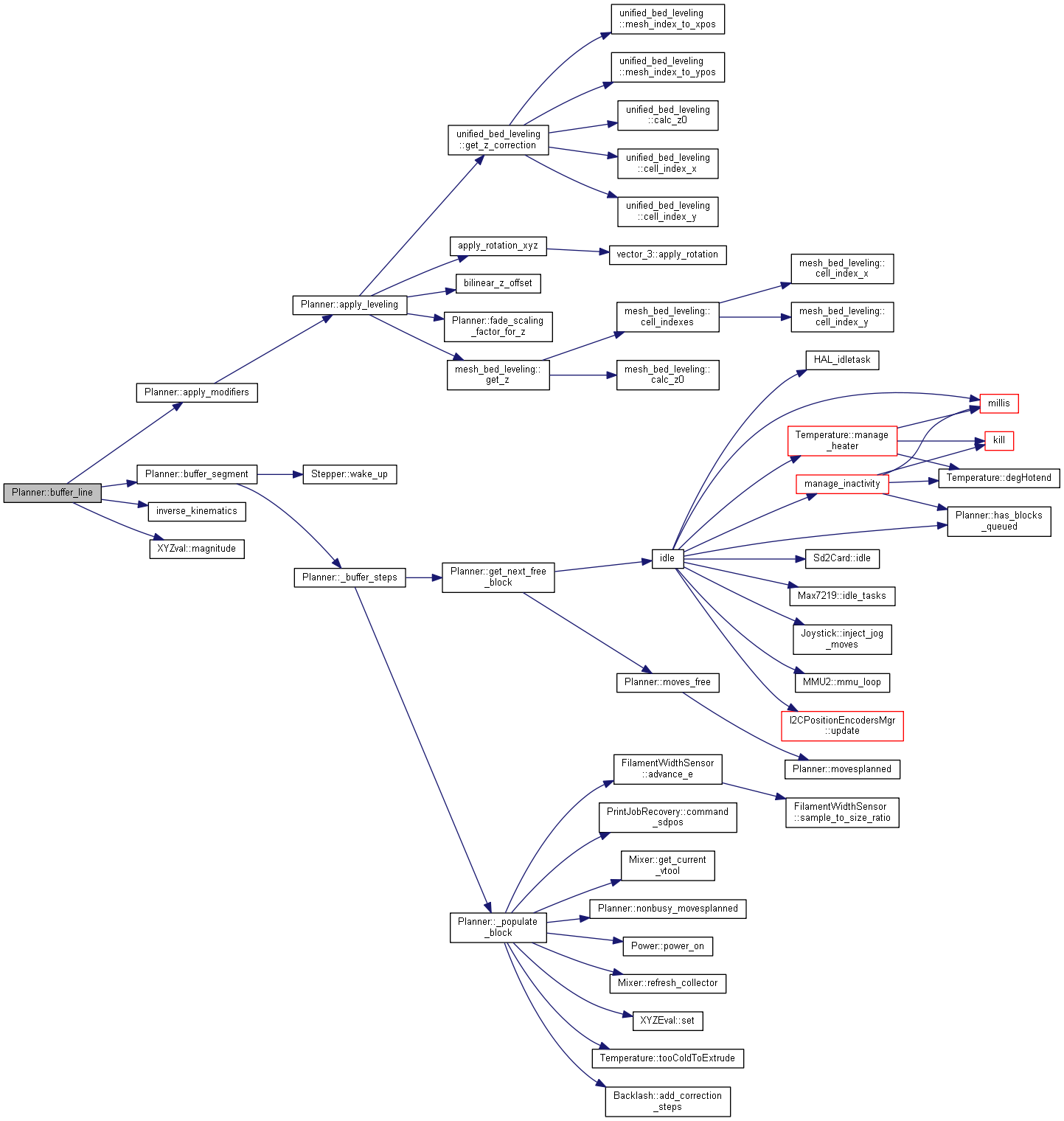

◆ buffer_line() [1/2]

Add a new linear movement to the buffer. The target is cartesian. It's translated to delta/scara if needed.

rx,ry,rz,e - target position in mm or degrees fr_mm_s - (target) speed of the move (mm/s) extruder - target extruder millimeters - the length of the movement, if known inv_duration - the reciprocal if the duration of the movement, if known (kinematic only if feeedrate scaling is enabled)

2669 #if HAS_POSITION_MODIFIERS

2675 #if DISABLED(CLASSIC_JERK)

2677 rx - position_cart.

x, ry - position_cart.y,

2678 rz - position_cart.z, e - position_cart.e

2681 const xyz_pos_t delta_mm_cart = { rx - position_cart.

x, ry - position_cart.y, rz - position_cart.z };

2684 float mm = millimeters;

2686 mm = (delta_mm_cart.

x != 0.0 || delta_mm_cart.

y != 0.0) ? delta_mm_cart.

magnitude() :

ABS(delta_mm_cart.

z);

2690 #if ENABLED(SCARA_FEEDRATE_SCALING)

2693 const float duration_recip = inv_duration ?: fr_mm_s / mm;

2702 , feedrate, extruder, mm

2704 position_cart.set(rx, ry, rz, e);

◆ buffer_line() [2/2]

688 return buffer_line(cart.

x, cart.

y, cart.

z, cart.

e, fr_mm_s, extruder, millimeters

689 #

if ENABLED(SCARA_FEEDRATE_SCALING)

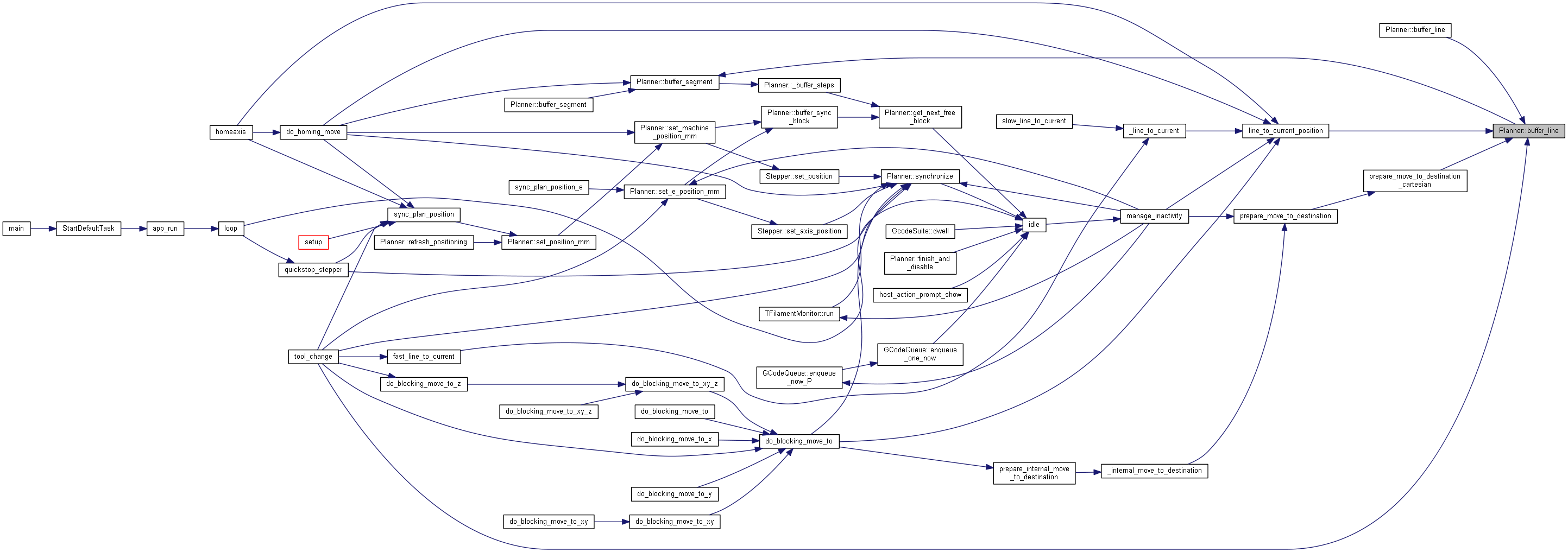

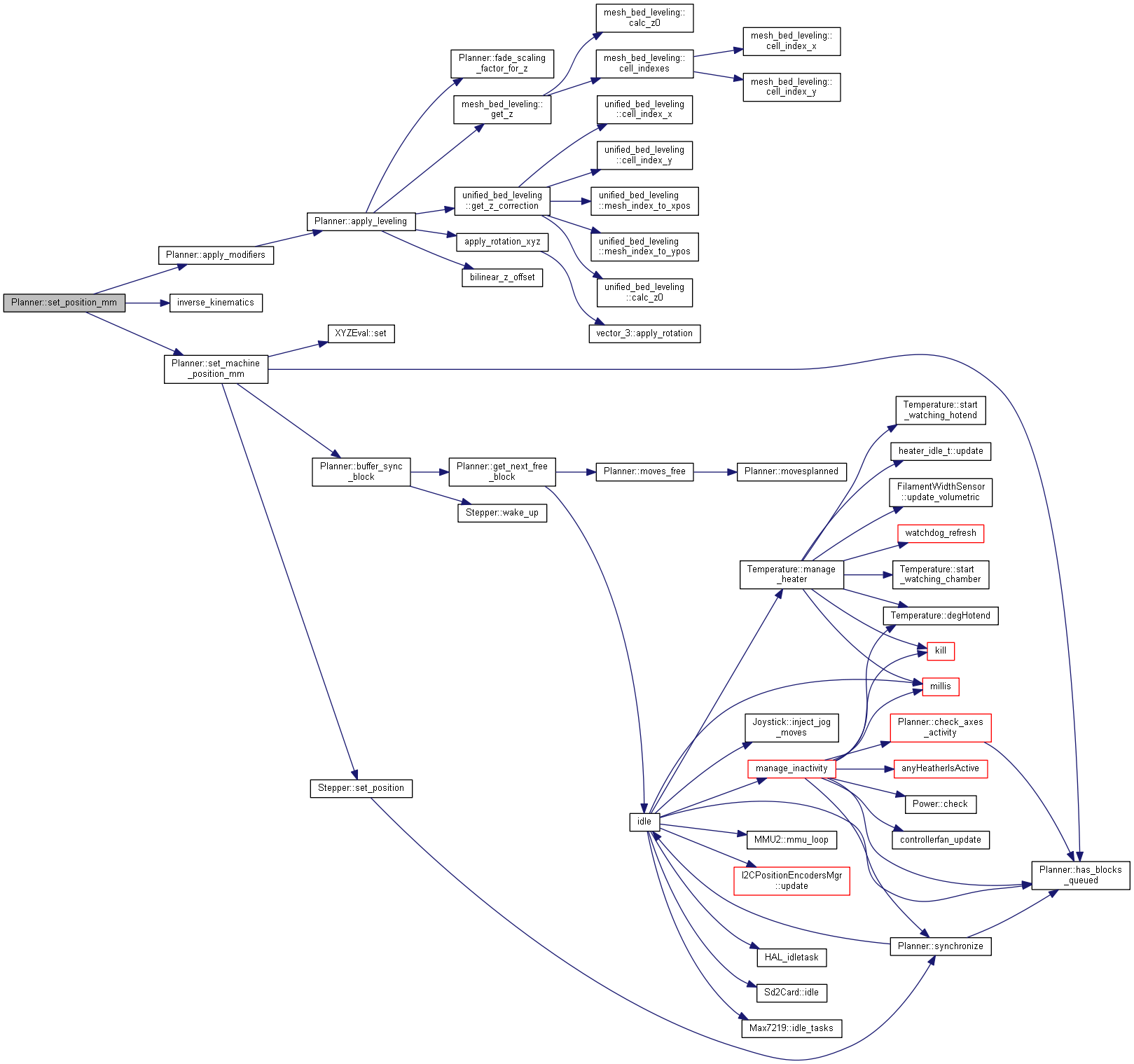

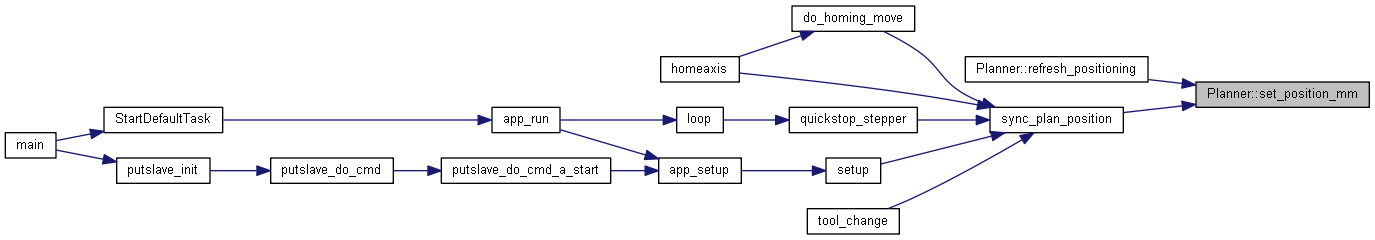

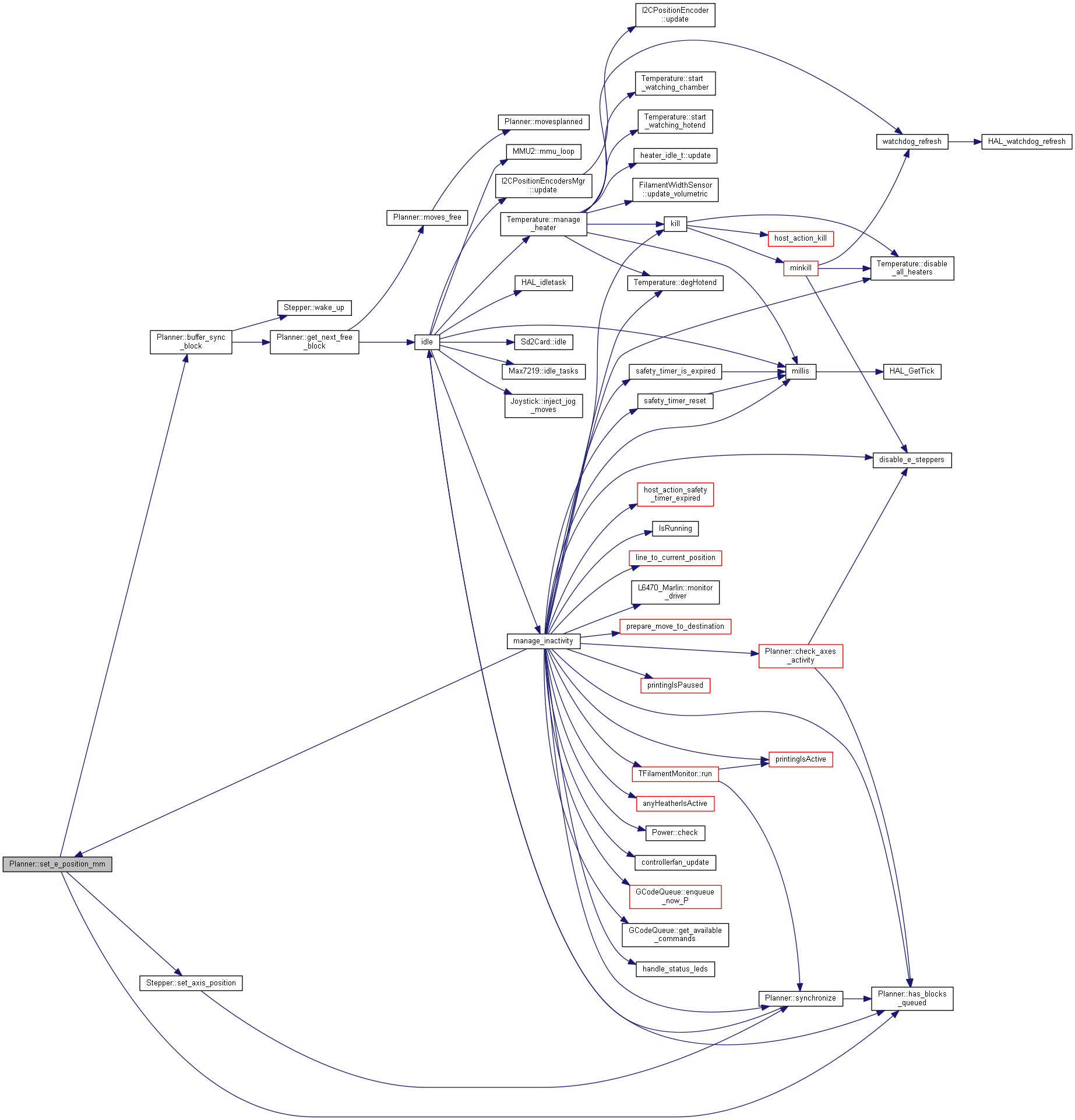

◆ set_position_mm() [1/2]

Set the planner.position and individual stepper positions. Used by G92, G28, G29, and other procedures.

The supplied position is in the cartesian coordinate space and is translated in to machine space as needed. Modifiers such as leveling and skew are also applied.

Multiplies by axis_steps_per_mm[] and does necessary conversion for COREXY / COREXZ / COREYZ to set the corresponding stepper positions.

Clears previous speed values.

2743 #if HAS_POSITION_MODIFIERS

2753 position_cart.set(rx, ry, rz, e);

◆ set_position_mm() [2/2]

◆ set_e_position_mm()

| void Planner::set_e_position_mm |

( |

const float & |

e | ) |

|

|

static |

Setters for planner position (also setting stepper position).

2766 #if ENABLED(DISTINCT_E_FACTORS)

2769 #if ENABLED(FWRETRACT)

2772 const float e_new = e;

2775 #if HAS_POSITION_FLOAT

2779 position_cart.e = e;

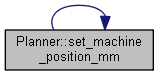

◆ set_machine_position_mm() [1/2]

Set the planner.position and individual stepper positions.

The supplied position is in machine space, and no additional conversions are applied.

Directly set the planner ABC position (and stepper positions) converting mm (or angles for SCARA) into steps.

The provided ABC position is in machine units.

2722 #if ENABLED(DISTINCT_E_FACTORS)

2725 #if HAS_POSITION_FLOAT

◆ set_machine_position_mm() [2/2]

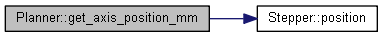

◆ get_axis_position_mm()

Get an axis position according to stepper position(s) For CORE machines apply translation from ABC to XYZ.

1530 if (axis == CORE_AXIS_1 || axis == CORE_AXIS_2) {

1543 axis_steps = (axis == CORE_AXIS_2 ? CORESIGN(p1 - p2) : p1 + p2) * 0.5f;

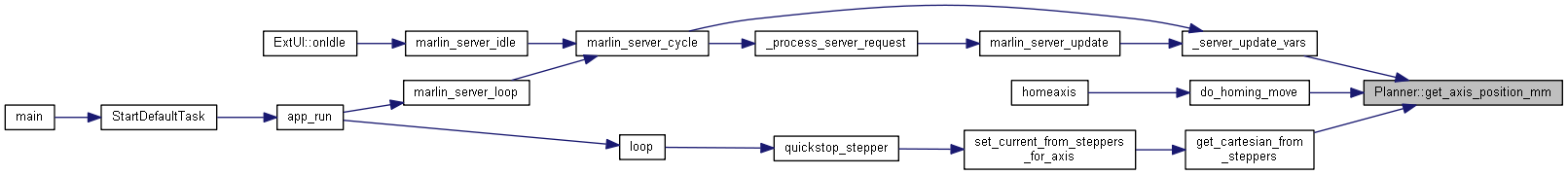

◆ quick_stop()

| void Planner::quick_stop |

( |

| ) |

|

|

static |

1495 clear_block_buffer_runtime();

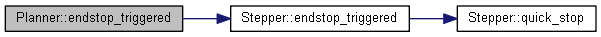

◆ endstop_triggered()

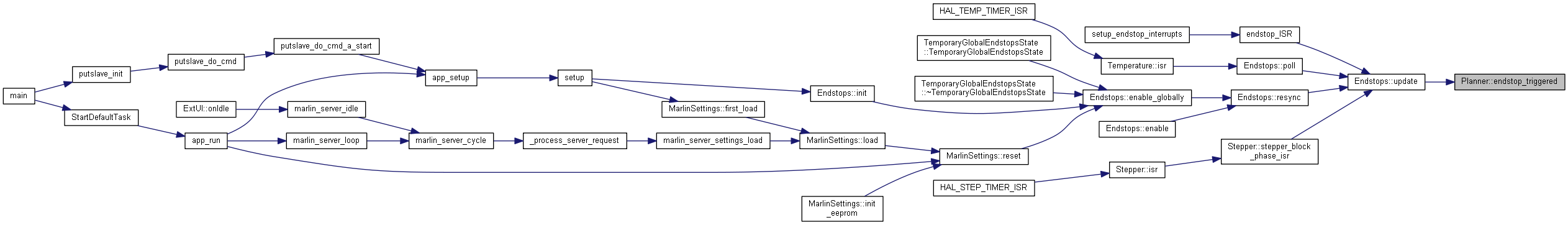

◆ triggered_position_mm()

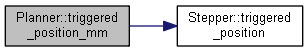

◆ synchronize()

| void Planner::synchronize |

( |

| ) |

|

|

static |

Block until all buffered steps are executed / cleaned

1559 #

if ENABLED(EXTERNAL_CLOSED_LOOP_CONTROLLER)

1560 || (

READ(CLOSED_LOOP_ENABLE_PIN) && !

READ(CLOSED_LOOP_MOVE_COMPLETE_PIN))

◆ finish_and_disable()

| void Planner::finish_and_disable |

( |

| ) |

|

|

static |

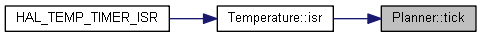

◆ tick()

| static void Planner::tick |

( |

| ) |

|

|

static |

753 #if ENABLED(SD_FINISHED_STEPPERRELEASE) && defined(SD_FINISHED_RELEASECOMMAND)

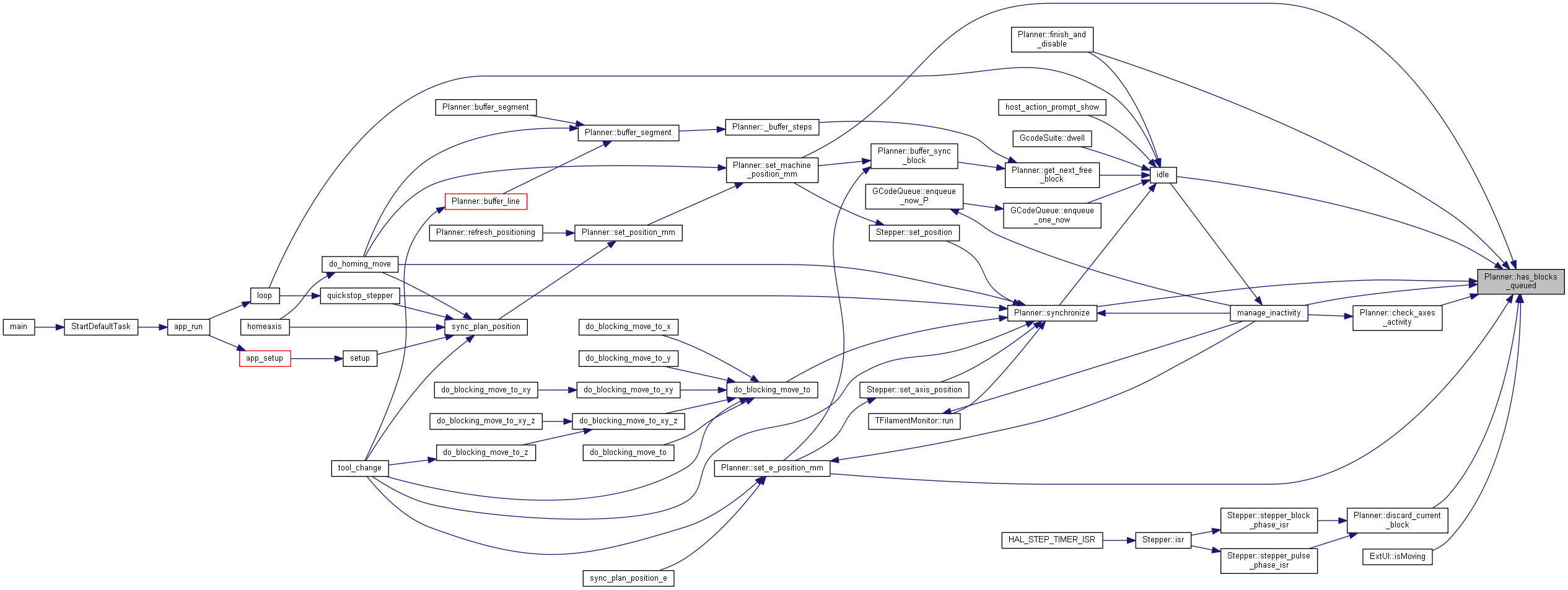

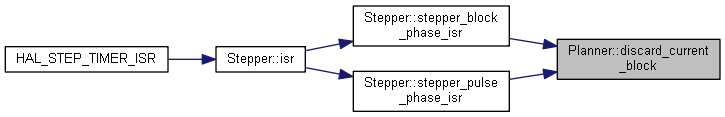

◆ has_blocks_queued()

Does the buffer have any blocks queued?

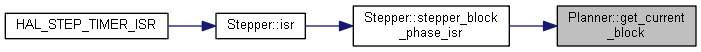

◆ get_current_block()

| static block_t* Planner::get_current_block |

( |

| ) |

|

|

static |

The current block. nullptr if the buffer is empty. This also marks the block as busy. WARNING: Called from Stepper ISR context!

793 block_buffer_runtime_us -= block->segment_time_us;

809 clear_block_buffer_runtime();

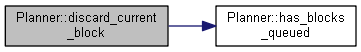

◆ discard_current_block()

"Discard" the block and "release" the memory. Called when the current block is no longer needed. NB: There MUST be a current block to call this function!!

◆ block_buffer

The move buffer, calculated in stepper steps

block_buffer is a ring buffer...

head,tail : indexes for write,read

head==tail : the buffer is empty

head!=tail : blocks are in the buffer

head==(tail-1)size : the buffer is full

Writer of head is Planner::buffer_segment(). Reader of tail is Stepper::isr(). Always consider tail busy / read-only

A ring buffer of moves described in steps

◆ block_buffer_head

| volatile uint8_t Planner::block_buffer_head |

|

static |

◆ block_buffer_nonbusy

| volatile uint8_t Planner::block_buffer_nonbusy |

|

static |

◆ block_buffer_planned

| volatile uint8_t Planner::block_buffer_planned |

|

static |

◆ block_buffer_tail

| volatile uint8_t Planner::block_buffer_tail |

|

static |

◆ cleaning_buffer_counter

| uint16_t Planner::cleaning_buffer_counter |

|

static |

◆ delay_before_delivering

| uint8_t Planner::delay_before_delivering |

|

static |

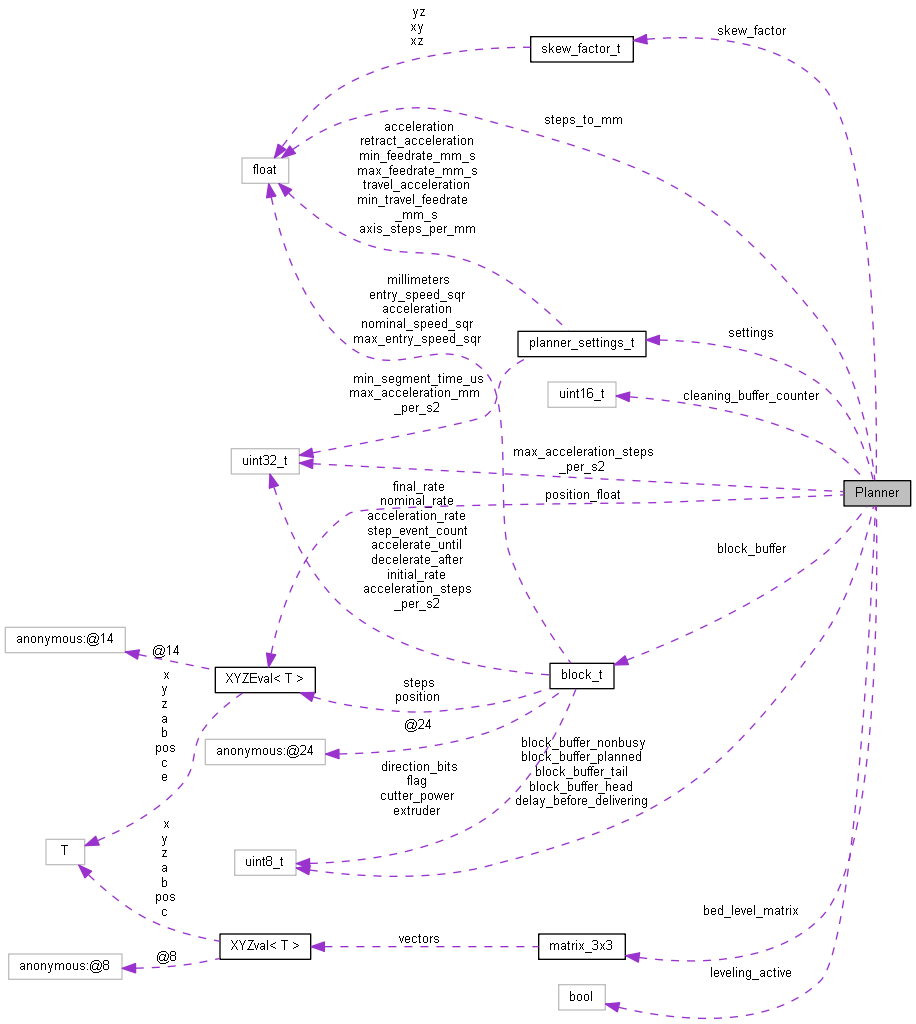

◆ settings

◆ max_acceleration_steps_per_s2

| uint32_t Planner::max_acceleration_steps_per_s2 |

|

static |

◆ steps_to_mm

| float Planner::steps_to_mm |

|

static |

◆ leveling_active

| bool Planner::leveling_active = false |

|

static |

◆ bed_level_matrix

◆ position_float

◆ skew_factor

#define enable_E2()

Definition: Marlin.h:276

#define WITHIN(N, L, H)

Definition: macros.h:195

static void buffer_sync_block()

Definition: planner.cpp:2529

T z

Definition: types.h:286

#define enable_E0()

Definition: Marlin.h:260

static void set_machine_position_mm(const float &a, const float &b, const float &c, const float &e)

Definition: planner.cpp:2721

static FORCE_INLINE bool tooColdToExtrude(const uint8_t)

Definition: temperature.h:314

#define NOLESS(v, n)

Definition: macros.h:127

#define DEFAULT_EJERK

Definition: Configuration_A3ides_2209_MINI.h:733

#define MIXER_POPULATE_BLOCK()

Definition: mixing.h:72

#define sq(x)

Definition: wiring_constants.h:83

T z

Definition: types.h:383

#define LIMIT_ACCEL_LONG(AXIS, INDX)

#define DEFAULT_MAX_ACCELERATION

Definition: Configuration_A3ides_2209_MINI.h:696

feedRate_t min_feedrate_mm_s

Definition: planner.h:186

volatile uint8_t flag

Definition: planner.h:97

T x

Definition: types.h:286

static float get_z(const xy_pos_t &pos)

Definition: mesh_bed_leveling.h:107

void disable_e_steppers()

Definition: Marlin.cpp:293

feedRate_t max_feedrate_mm_s[XYZE_N]

Definition: planner.h:182

#define MSG_ERR_COLD_EXTRUDE_STOP

Definition: language.h:242

static matrix_3x3 bed_level_matrix

Definition: planner.h:278

#define enable_E5()

Definition: Marlin.h:300

#define CORE_IS_XY

Definition: Conditionals_post.h:101

static cutter_power_t power

Definition: spindle_laser.h:48

GCodeQueue queue

Definition: queue.cpp:28

#define BLOCK_MOD(n)

Definition: planner.h:176

constexpr xy_pos_t level_fulcrum

Definition: planner.cpp:1369

#define enable_E3()

Definition: Marlin.h:284

#define UNEAR_ZERO(x)

Definition: macros.h:269

static uint32_t command_sdpos()

Definition: power_loss_recovery.h:135

Stepper stepper

Definition: stepper.cpp:82

static bool buffer_segment(const float &a, const float &b, const float &c, const float &e, const feedRate_t &fr_mm_s, const uint8_t extruder, const float &millimeters=0.0)

Definition: planner.cpp:2568

float retract_acceleration

Definition: planner.h:183

#define _MAX(V...)

Definition: macros.h:346

uint32_t acceleration_steps_per_s2

Definition: planner.h:147

static uint32_t max_acceleration_steps_per_s2[XYZE_N]

Definition: planner.h:253

static bool _buffer_steps(const xyze_long_t &target, const xyze_pos_t &target_float, feedRate_t fr_mm_s, const uint8_t extruder, const float &millimeters=0.0)

Definition: planner.cpp:1578

static bool leveling_active

Definition: planner.h:276

#define MIN_STEPS_PER_SEGMENT

Definition: Configuration_A3ides_2209_MINI_adv.h:1108

static void advance_e(const float &e_move)

Definition: filwidth.h:80

#define disable_Z()

Definition: Marlin.h:143

T e

Definition: types.h:383

static FORCE_INLINE uint8_t movesplanned()

Definition: planner.h:543

uint8_t i

Definition: screen_test_graph.c:72

#define _MIN(V...)

Definition: macros.h:333

#define LOOP_XYZE_N(VAR)

Definition: types.h:62

static volatile uint8_t block_buffer_tail

Definition: planner.h:227

static void wake_up()

Definition: stepper.cpp:342

static void endstop_triggered(const AxisEnum axis)

Definition: stepper.cpp:2237

#define disable_Y()

Definition: Marlin.h:104

#define enable_Z()

Definition: Marlin.h:142

#define CACHED_SQRT(N, V)

#define IS_KINEMATIC

Definition: Conditionals_LCD.h:545

PrintJobRecovery recovery

abce_ulong_t steps

Definition: planner.h:107

static volatile uint8_t block_buffer_head

Definition: planner.h:227

#define STEPPER_ISR_ENABLED()

Definition: HAL.h:143

float feedRate_t

Definition: types.h:80

static matrix_3x3 transpose(const matrix_3x3 &original)

Definition: vector_3.cpp:131

static xyze_pos_t position_float

Definition: planner.h:292

bool extruder_duplication_enabled

Definition: motion.cpp:876

static void set_axis_position(const AxisEnum a, const int32_t &v)

Definition: stepper.h:446

SpindleLaser cutter

Definition: spindle_laser.cpp:33

void set_to_identity()

Definition: vector_3.cpp:94

Definition: vector_3.h:73

static FORCE_INLINE block_t * get_next_free_block(uint8_t &next_buffer_head, const uint8_t count=1)

Definition: planner.h:564

#define HEATER_2_PIN

Definition: pins_COHESION3D_REMIX.h:116

#define NOMORE(v, n)

Definition: macros.h:133

cutter_power_t cutter_power

Definition: planner.h:153

FI T magnitude() const

Definition: types.h:295

int8_t pin_t

Definition: HAL.h:65

#define ABS(a)

Definition: macros.h:266

static volatile uint8_t block_buffer_nonbusy

Definition: planner.h:227

static block_t block_buffer[BLOCK_BUFFER_SIZE]

Definition: planner.h:226

#define E_AXIS_N(E)

Definition: Conditionals_LCD.h:454

#define AUTO_BED_LEVELING_BILINEAR

Definition: Configuration_A3ides_2209_MINI.h:1092

static FORCE_INLINE void clear_block_buffer()

Definition: planner.h:549

T a

Definition: types.h:384

#define SERIAL_ECHO_MSG(S)

Definition: serial.h:183

abce_long_t position

Definition: planner.h:108

#define RADIANS(d)

Definition: macros.h:98

T c

Definition: types.h:384

#define PSTR(str)

Definition: pgmspace.h:31

xyze_pos_t current_position

Definition: motion.cpp:102

static FORCE_INLINE void apply_modifiers(xyze_pos_t &pos, bool leveling=false)

Definition: planner.h:499

#define LROUND(x)

Definition: macros.h:285

#define HAS_LEVELING

Definition: Conditionals_post.h:1408

void add_correction_steps(const int32_t &da, const int32_t &db, const int32_t &dc, const uint8_t dm, block_t *const block)

#define BLOCK_BUFFER_SIZE

Definition: Configuration_A3ides_2209_MINI_adv.h:1167

void apply_rotation_xyz(const matrix_3x3 &matrix, float &_x, float &_y, float &_z)

Definition: vector_3.cpp:88

void init()

Definition: planner.cpp:234

T b

Definition: types.h:384

float entry_speed_sqr

Definition: planner.h:100

uint32_t acceleration_rate

Definition: planner.h:133

FilamentWidthSensor filwidth

#define ENABLE_STEPPER_DRIVER_INTERRUPT()

Definition: HAL.h:141

#define LOOP_XYZ(VAR)

Definition: types.h:60

float travel_acceleration

Definition: planner.h:183

float axis_steps_per_mm[XYZE_N]

Definition: planner.h:181

#define DISABLED(V...)

Definition: macros.h:178

float millimeters

Definition: planner.h:100

#define CEIL(x)

Definition: macros.h:283

#define HAS_POSITION_FLOAT

Definition: planner.h:174

float nominal_speed_sqr

Definition: planner.h:100

static void refresh_collector(const float proportion=1.0, const uint8_t t=selected_vtool, float(&c)[MIXING_STEPPERS]=collector)

float acceleration

Definition: planner.h:183

static int32_t triggered_position(const AxisEnum axis)

Definition: stepper.cpp:2258

T x

Definition: types.h:383

uint8_t baricuda_valve_pressure

uint32_t max_acceleration_mm_per_s2[XYZE_N]

Definition: planner.h:179

static void reset_acceleration_rates()

Definition: planner.cpp:2788

#define HEATER_1_PIN

Definition: pins_RAMPS_LINUX.h:196

static bool buffer_line(const float &rx, const float &ry, const float &rz, const float &e, const feedRate_t &fr_mm_s, const uint8_t extruder, const float millimeters=0.0)

Definition: planner.cpp:2663

#define enable_X()

Definition: Marlin.h:76

list a

Definition: createSpeedLookupTable.py:29

static FORCE_INLINE void quick_stop()

Definition: stepper.h:375

#define enable_Y()

Definition: Marlin.h:103

void disable_all_steppers()

Definition: Marlin.cpp:308

static float get_z_correction(const float &rx0, const float &ry0)

Definition: ubl.h:238

FI void set(const T px)

Definition: types.h:391

#define SQRT(x)

Definition: macros.h:281

T x

Definition: types.h:185

float max_entry_speed_sqr

Definition: planner.h:100

#define MIXER_STEPPER_LOOP(VAR)

Definition: mixing.h:68

#define BLOCK_DELAY_FOR_1ST_MOVE

Definition: planner.cpp:109

#define enable_E1()

Definition: Marlin.h:268

const uint8_t[]

Definition: 404_html.c:3

#define DEFAULT_MAX_FEEDRATE

Definition: Configuration_A3ides_2209_MINI.h:687

float bilinear_z_offset(const xy_pos_t &raw)

uint8_t direction_bits

Definition: planner.h:136

#define DISABLE_STEPPER_DRIVER_INTERRUPT()

Definition: HAL.h:142

#define HYPOT(x, y)

Definition: macros.h:287

T y

Definition: types.h:286

static float steps_to_mm[XYZE_N]

Definition: planner.h:254

static uint16_t cleaning_buffer_counter

Definition: planner.h:231

void inverse_kinematics(const xyz_pos_t &raw)

#define disable_X()

Definition: Marlin.h:77

uint32_t step_event_count

Definition: planner.h:110

#define enable_E4()

Definition: Marlin.h:292

#define MSG_ERR_LONG_EXTRUDE_STOP

Definition: language.h:243

void limit_and_warn(float &val, const uint8_t axis, PGM_P const setting_name, const xyze_float_t &max_limit)

Definition: planner.cpp:2812

static bool _populate_block(block_t *const block, bool split_move, const xyze_long_t &target, const xyze_pos_t &target_float, feedRate_t fr_mm_s, const uint8_t extruder, const float &millimeters=0.0)

Definition: planner.cpp:1641

static FORCE_INLINE uint8_t moves_free()

Definition: planner.h:555

#define EXTRUDERS

Definition: Configuration_A3ides_2209_MINI.h:148

#define DEBUGGING(F)

Definition: serial.h:47

#define FAN_COUNT

Definition: Conditionals_post.h:1292

float acceleration

Definition: planner.h:100

#define MINIMUM_PLANNER_SPEED

Definition: Configuration_A3ides_2209_MINI_adv.h:545

static FORCE_INLINE float fade_scaling_factor_for_z(const float &)

Definition: planner.h:445

uint8_t baricuda_e_to_p_pressure

static FORCE_INLINE uint8_t nonbusy_movesplanned()

Definition: planner.h:546

uint32_t nominal_rate

Definition: planner.h:147

#define TEST(n, b)

Definition: macros.h:81

T y

Definition: types.h:185

static int32_t position(const AxisEnum axis)

Definition: stepper.cpp:2214

static void inject_P(PGM_P const pgcode)

Definition: queue.cpp:206

#define SBI(A, B)

Definition: macros.h:85

static planner_settings_t settings

Definition: planner.h:251

#define SERIAL_ECHOLNPGM(S)

Definition: serial.h:174

static void set_position_mm(const float &rx, const float &ry, const float &rz, const float &e)

Definition: planner.cpp:2741

static void apply_leveling(xyz_pos_t &raw)

Definition: planner.cpp:1381

list b

Definition: createSpeedLookupTable.py:30

void analogWrite(uint32_t ulPin, uint32_t ulValue)

Definition: wiring_analog.c:12

#define LOOP_XYZE(VAR)

Definition: types.h:61

void idle()

Definition: Marlin.cpp:629

#define READ(IO)

Definition: fastio.h:95

#define CORE_IS_XZ

Definition: Conditionals_post.h:102

feedRate_t min_travel_feedrate_mm_s

Definition: planner.h:186

static void unapply_leveling(xyz_pos_t &raw)

Definition: planner.cpp:1415

Temperature thermalManager

Definition: temperature.cpp:89

#define UNUSED(X)

Definition: stm32f4xx_hal_def.h:74

FI void reset()

Definition: types.h:387

static volatile uint8_t block_buffer_planned

Definition: planner.h:227

static constexpr uint8_t extruder

Definition: planner.h:115

uint32_t millis_t

Definition: millis_t.h:26

#define LIMIT_ACCEL_FLOAT(AXIS, INDX)

#define CORE_IS_YZ

Definition: Conditionals_post.h:103

static FORCE_INLINE uint8_t get_current_vtool()

Definition: mixing.h:111

static uint8_t delay_before_delivering

Definition: planner.h:232

constexpr uint8_t active_extruder

Definition: motion.h:107

static void set_position(const int32_t &a, const int32_t &b, const int32_t &c, const int32_t &e)

Definition: stepper.h:437

uint32_t min_segment_time_us

Definition: planner.h:179

#define ENABLED(V...)

Definition: macros.h:177

static FORCE_INLINE bool has_blocks_queued()

Definition: planner.h:762

T y

Definition: types.h:383

static void refresh()

Definition: spindle_laser.h:56

#define STEPPER_TIMER_RATE

Definition: HAL.h:133

#define EXTRUDE_MAXLENGTH

Definition: Configuration_A3ides_2209_MINI.h:524