|

Prusa MINI Firmware overview

|

◆ DEBUG_OUT

| #define DEBUG_OUT ENABLED(DEBUG_LEVELING_FEATURE) |

Marlin 3D Printer Firmware Copyright (c) 2019 MarlinFirmware [https://github.com/MarlinFirmware/Marlin]

Based on Sprinter and grbl. Copyright (c) 2011 Camiel Gubbels / Erik van der Zalm

This program is free software: you can redistribute it and/or modify it under the terms of the GNU General Public License as published by the Free Software Foundation, either version 3 of the License, or (at your option) any later version.

This program is distributed in the hope that it will be useful, but WITHOUT ANY WARRANTY; without even the implied warranty of MERCHANTABILITY or FITNESS FOR A PARTICULAR PURPOSE. See the GNU General Public License for more details.

You should have received a copy of the GNU General Public License along with this program. If not, see http://www.gnu.org/licenses/.

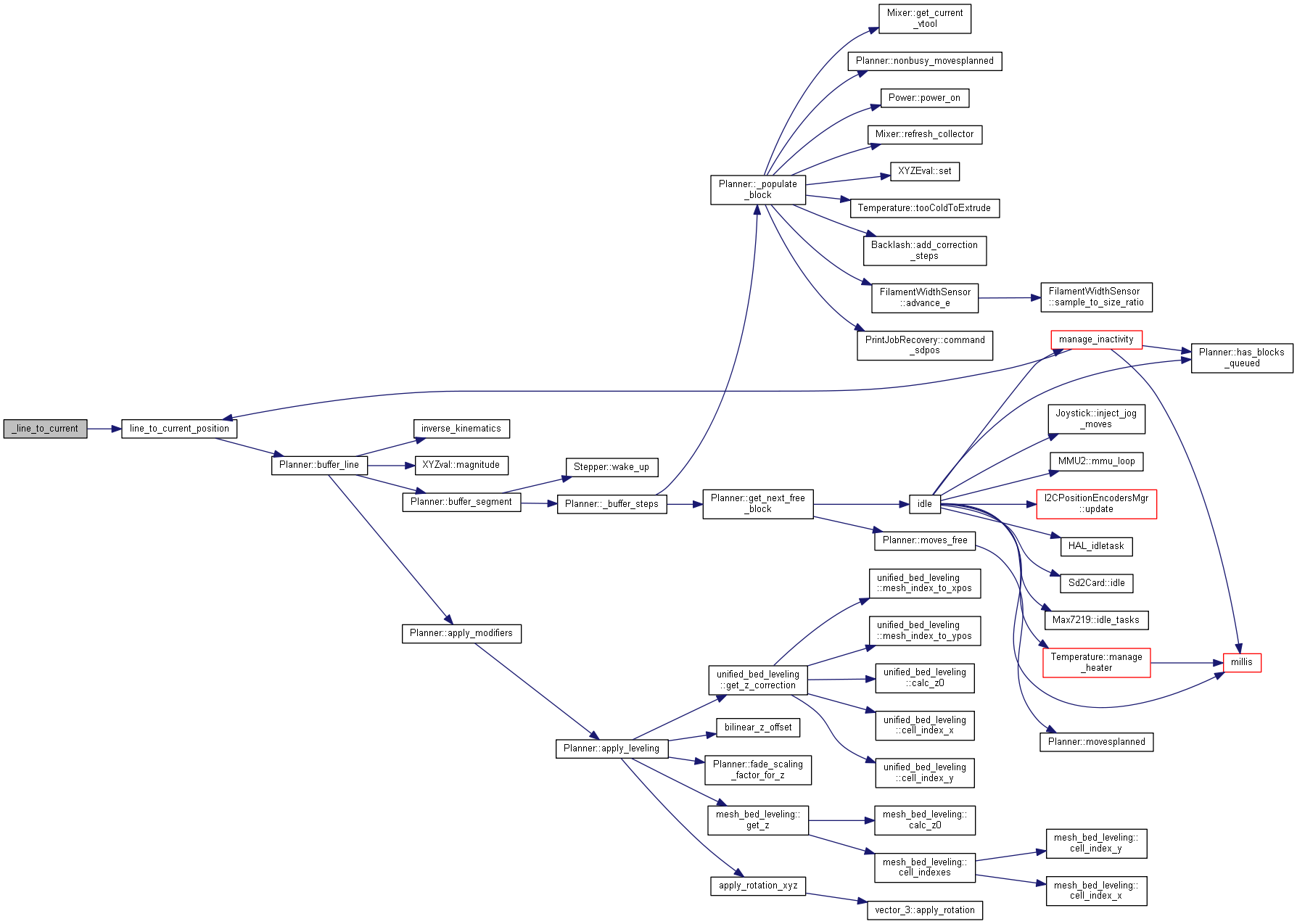

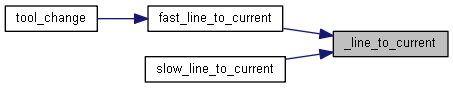

◆ _line_to_current()

◆ slow_line_to_current()

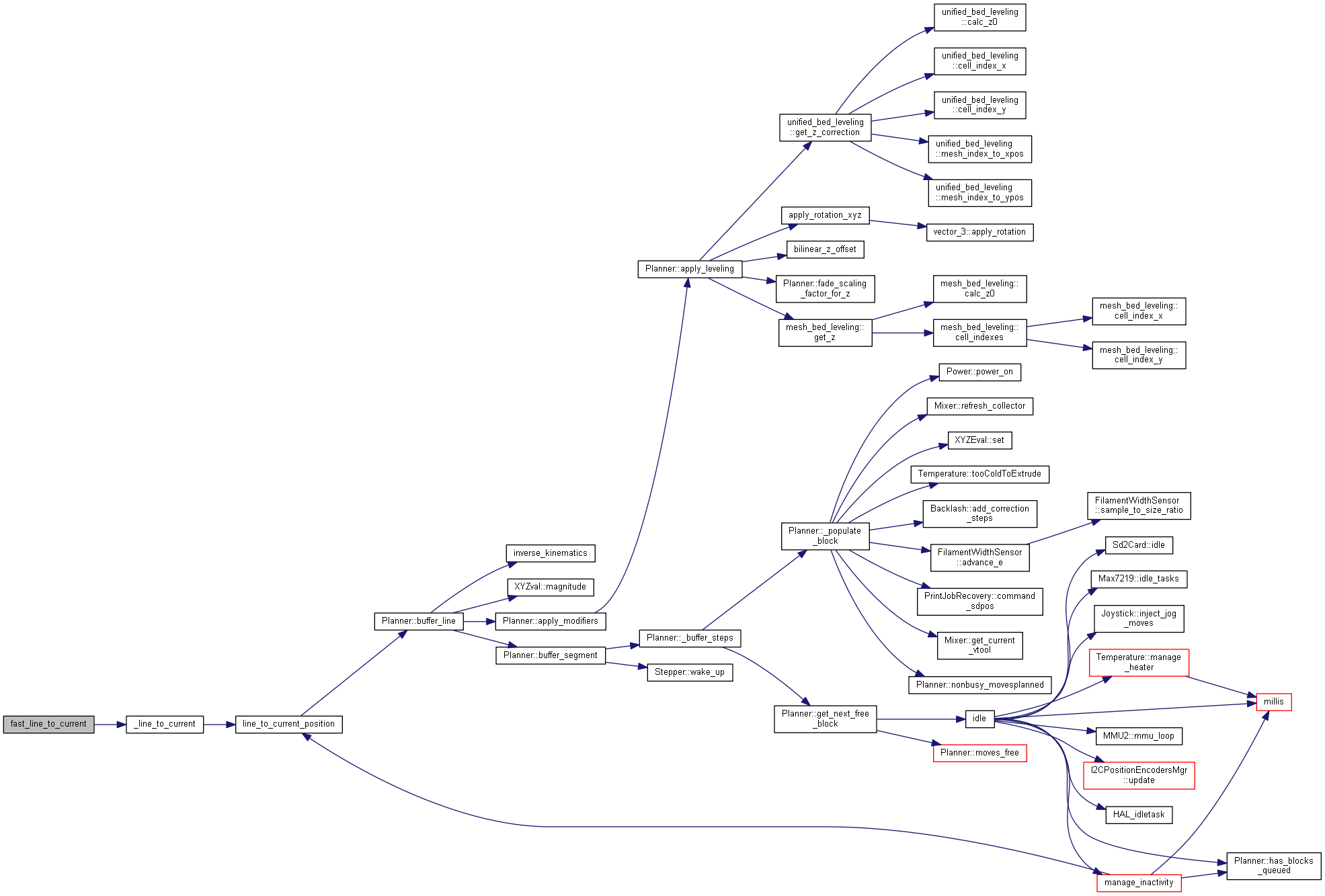

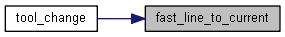

◆ fast_line_to_current()

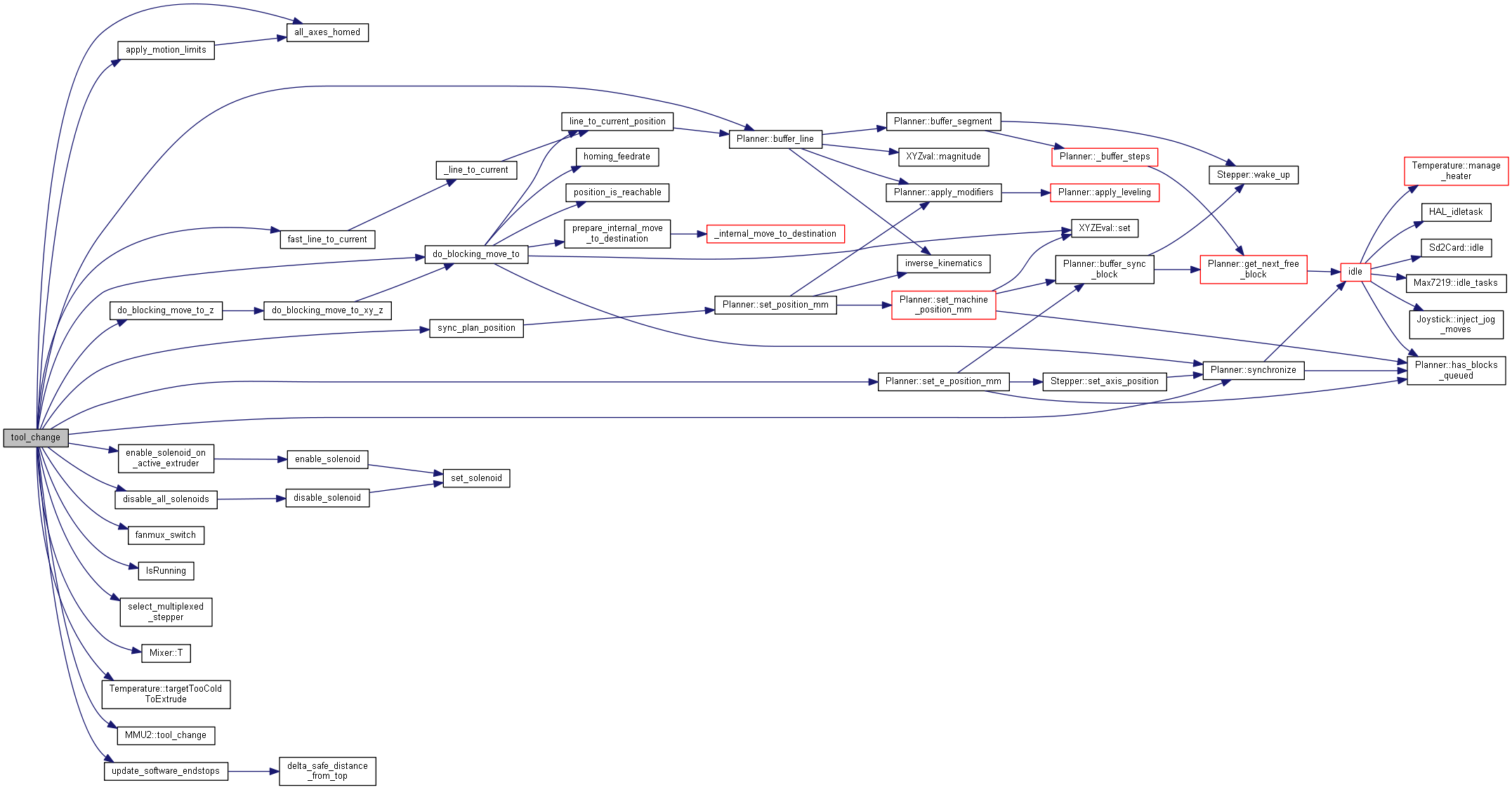

◆ tool_change()

Perform a tool-change, which may result in moving the previous tool out of the way and the new tool into place.

773 #if ENABLED(MAGNETIC_SWITCHING_TOOLHEAD)

777 #if ENABLED(MIXING_EXTRUDER)

782 return invalid_extruder_error(new_tool);

784 #if MIXING_VIRTUAL_TOOLS > 1

789 #elif ENABLED(PRUSA_MMU2)

804 if (new_tool) invalid_extruder_error(new_tool);

807 #else // EXTRUDERS > 1

811 #if ENABLED(DUAL_X_CARRIAGE) // Only T0 allowed if the Printer is in DXC_DUPLICATION_MODE or DXC_MIRRORED_MODE

812 if (new_tool != 0 && dxc_is_duplicating())

813 return invalid_extruder_error(new_tool);

817 return invalid_extruder_error(new_tool);

825 ui.return_to_status();

828 #if ENABLED(DUAL_X_CARRIAGE)

829 const bool idex_full_control = dual_x_carriage_mode == DXC_FULL_CONTROL_MODE;

831 constexpr

bool idex_full_control =

false;

835 const bool can_move_away = !no_move && !idex_full_control;

837 #if ENABLED(TOOLCHANGE_FILAMENT_SWAP)

838 const bool should_swap = can_move_away && toolchange_settings.swap_length;

839 #if ENABLED(PREVENT_COLD_EXTRUSION)

842 constexpr

bool too_cold =

false;

847 #if ENABLED(SINGLENOZZLE)

853 #if ENABLED(ADVANCED_PAUSE_FEATURE)

854 do_pause_e_move(-toolchange_settings.swap_length,

MMM_TO_MMS(toolchange_settings.retract_speed));

862 #endif // TOOLCHANGE_FILAMENT_SWAP

869 if (new_tool != old_tool) {

871 #if SWITCHING_NOZZLE_TWO_SERVOS

872 raise_nozzle(old_tool);

877 #if HAS_SOFTWARE_ENDSTOPS

878 #if HAS_HOTEND_OFFSET

879 #define _EXT_ARGS , old_tool, new_tool

884 #if DISABLED(DUAL_X_CARRIAGE)

892 #if DISABLED(SWITCHING_NOZZLE)

896 #if HAS_SOFTWARE_ENDSTOPS

900 #if ENABLED(TOOLCHANGE_PARK)

908 #if HAS_HOTEND_OFFSET

910 #if ENABLED(DUAL_X_CARRIAGE)

917 #if ENABLED(DUAL_X_CARRIAGE)

918 dualx_tool_change(new_tool, no_move);

919 #elif ENABLED(PARKING_EXTRUDER) // Dual Parking extruder

920 parking_extruder_tool_change(new_tool, no_move);

921 #elif ENABLED(MAGNETIC_PARKING_EXTRUDER) // Magnetic Parking extruder

922 magnetic_parking_extruder_tool_change(new_tool);

923 #elif ENABLED(SWITCHING_TOOLHEAD) // Switching Toolhead

924 switching_toolhead_tool_change(new_tool, no_move);

925 #elif ENABLED(MAGNETIC_SWITCHING_TOOLHEAD) // Magnetic Switching Toolhead

926 magnetic_switching_toolhead_tool_change(new_tool, no_move);

927 #elif ENABLED(ELECTROMAGNETIC_SWITCHING_TOOLHEAD) // Magnetic Switching ToolChanger

928 em_switching_toolhead_tool_change(new_tool, no_move);

929 #elif ENABLED(SWITCHING_NOZZLE) && !SWITCHING_NOZZLE_TWO_SERVOS // Switching Nozzle (single servo)

933 #if HAS_SOFTWARE_ENDSTOPS

937 move_nozzle_servo(new_tool);

940 #if DISABLED(DUAL_X_CARRIAGE)

955 constexpr

bool safe_to_move =

true;

959 if (safe_to_move && !no_move &&

IsRunning()) {

961 #if ENABLED(SINGLENOZZLE)

967 singlenozzle_temp[old_tool] =

thermalManager.temp_hotend[0].target;

968 if (singlenozzle_temp[new_tool] && singlenozzle_temp[new_tool] != singlenozzle_temp[old_tool]) {

977 #if ENABLED(TOOLCHANGE_FILAMENT_SWAP)

978 if (should_swap && !too_cold) {

979 #if ENABLED(ADVANCED_PAUSE_FEATURE)

980 do_pause_e_move(toolchange_settings.swap_length,

MMM_TO_MMS(toolchange_settings.prime_speed));

981 do_pause_e_move(toolchange_settings.extra_prime, ADVANCED_PAUSE_PURGE_FEEDRATE);

994 #if ENABLED(MAGNETIC_SWITCHING_TOOLHEAD)

996 if (

destination.

y < SWITCHING_TOOLHEAD_Y_POS + SWITCHING_TOOLHEAD_Y_CLEAR) {

1006 if (can_move_away) {

1007 #if ENABLED(TOOLCHANGE_NO_RETURN)

1019 #if ENABLED(DUAL_X_CARRIAGE)

1020 active_extruder_parked =

false;

1023 #if ENABLED(SWITCHING_NOZZLE)

1030 #if ENABLED(PRUSA_MMU2)

1034 #if SWITCHING_NOZZLE_TWO_SERVOS

1035 lower_nozzle(new_tool);

1042 #if ENABLED(EXT_SOLENOID) && DISABLED(PARKING_EXTRUDER)

1047 #if ENABLED(MK2_MULTIPLEXER)

1048 if (new_tool >=

E_STEPPERS)

return invalid_extruder_error(new_tool);

1052 #if DO_SWITCH_EXTRUDER

1064 #endif // EXTRUDERS > 1

float delta_clip_start_height

T z

Definition: types.h:286

void enable_solenoid_on_active_extruder()

Definition: solenoid.cpp:77

#define MIXING_VIRTUAL_TOOLS

Definition: mixing.h:47

T z

Definition: types.h:383

static void synchronize()

Definition: planner.cpp:1556

xyz_pos_t max

Definition: motion.h:139

T x

Definition: types.h:286

feedRate_t max_feedrate_mm_s[XYZE_N]

Definition: planner.h:182

#define DEBUG_ECHOLNPGM(...)

Definition: debug_out.h:79

#define _MAX(V...)

Definition: macros.h:346

void do_blocking_move_to_z(const float &rz, const feedRate_t &fr_mm_s)

Definition: motion.cpp:450

T e

Definition: types.h:383

xyze_pos_t destination

Definition: motion.cpp:110

#define DEBUG_ECHOLNPAIR(...)

Definition: debug_out.h:82

#define SERIAL_ECHO_START()

Definition: serial.h:179

bool IsRunning()

Definition: Marlin.h:331

#define NOMORE(v, n)

Definition: macros.h:133

void disable_all_solenoids()

Definition: solenoid.cpp:79

#define SERIAL_ECHO_MSG(S)

Definition: serial.h:183

xyze_pos_t current_position

Definition: motion.cpp:102

static FORCE_INLINE bool targetTooColdToExtrude(const uint8_t)

Definition: temperature.h:315

void line_to_current_position(const feedRate_t &fr_mm_s)

Definition: motion.cpp:285

void do_blocking_move_to(const float rx, const float ry, const float rz, const feedRate_t &fr_mm_s)

Definition: motion.cpp:344

void sync_plan_position()

Definition: motion.cpp:216

#define REMEMBER(N, X, V...)

Definition: utility.h:76

void

Definition: png.h:1083

T x

Definition: types.h:383

#define XY_PROBE_FEEDRATE_MM_S

Definition: motion.h:77

static bool buffer_line(const float &rx, const float &ry, const float &rz, const float &e, const feedRate_t &fr_mm_s, const uint8_t extruder, const float millimeters=0.0)

Definition: planner.cpp:2663

feedRate_t feedrate_mm_s

Definition: motion.cpp:138

#define SERIAL_ECHOLNPAIR(V...)

Definition: serial.h:144

#define DEBUG_POS(...)

Definition: debug_out.h:87

const uint8_t[]

Definition: 404_html.c:3

void update_software_endstops(const AxisEnum axis)

Definition: motion.cpp:503

#define E_STEPPERS

Definition: Conditionals_LCD.h:429

T y

Definition: types.h:286

void select_multiplexed_stepper(const uint8_t e)

static FORCE_INLINE void T(const uint_fast8_t c)

Definition: mixing.h:113

constexpr xyz_pos_t hotend_offset[1]

Definition: motion.h:136

static void set_e_position_mm(const float &e)

Definition: planner.cpp:2764

#define EXTRUDERS

Definition: Configuration_A3ides_2209_MINI.h:148

void apply_motion_limits(xyz_pos_t &target)

Definition: motion.cpp:589

#define DEBUGGING(F)

Definition: serial.h:47

#define MSG_ERR_HOTEND_TOO_COLD

Definition: language.h:244

#define MMM_TO_MMS(MM_M)

Definition: types.h:83

static planner_settings_t settings

Definition: planner.h:251

#define MSG_ACTIVE_EXTRUDER

Definition: language.h:183

axis_limits_t soft_endstop

Definition: motion.cpp:489

Temperature thermalManager

Definition: temperature.cpp:89

#define UNUSED(X)

Definition: stm32f4xx_hal_def.h:74

#define TEMPORARY_BED_LEVELING_STATE(enable)

Definition: bedlevel.h:54

constexpr uint8_t active_extruder

Definition: motion.h:107

static void tool_change(uint8_t index)

Planner planner

Definition: planner.cpp:111

FORCE_INLINE bool all_axes_homed()

Definition: motion.h:44

T y

Definition: types.h:383

void fanmux_switch(const uint8_t e)