|

Prusa MINI Firmware overview

|

#include <gcode.h>

◆ axis_is_relative()

◆ set_relative_mode()

| static void GcodeSuite::set_relative_mode |

( |

const bool |

rel | ) |

|

|

static |

◆ set_e_relative()

| static void GcodeSuite::set_e_relative |

( |

| ) |

|

|

static |

◆ set_e_absolute()

| static void GcodeSuite::set_e_absolute |

( |

| ) |

|

|

static |

◆ reset_stepper_timeout()

◆ get_target_extruder_from_command()

| int8_t GcodeSuite::get_target_extruder_from_command |

( |

| ) |

|

|

static |

Get the target extruder from the T parameter or the active_extruder Return -1 if the T parameter is out of range

81 const int8_t e =

parser.value_byte();

◆ get_target_e_stepper_from_command()

| int8_t GcodeSuite::get_target_e_stepper_from_command |

( |

| ) |

|

|

static |

Get the target e stepper from the T parameter Return -1 if the T parameter is out of range or unspecified

96 const int8_t e =

parser.intval(

'T', -1);

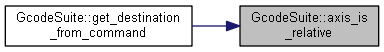

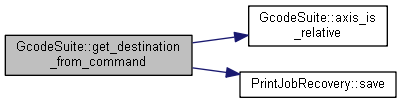

◆ get_destination_from_command()

| void GcodeSuite::get_destination_from_command |

( |

| ) |

|

|

static |

Set XYZE destination and feedrate from the current GCode command

- Set destination from included axis codes

- Set to current for missing axis codes

- Set the feedrate, if included

126 #if ENABLED(POWER_LOSS_RECOVERY) && !PIN_EXISTS(POWER_LOSS)

132 if (

parser.linearval(

'F') > 0)

135 #if ENABLED(PRINTCOUNTER)

141 #if BOTH(MIXING_EXTRUDER, DIRECT_MIXING_IN_G1)

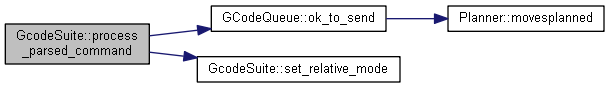

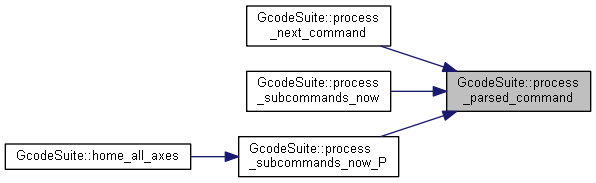

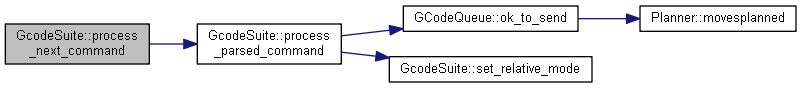

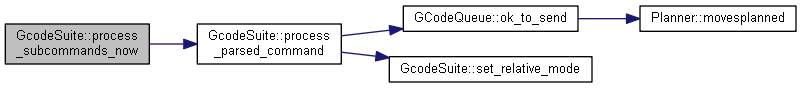

◆ process_parsed_command()

| void GcodeSuite::process_parsed_command |

( |

const bool |

no_ok = false | ) |

|

|

static |

When G29_RETRY_AND_RECOVER is enabled, call G29() in a loop with recovery and retry handling. Process the parsed command and dispatch it to its handler

199 switch (

parser.command_letter) {

200 case 'G':

switch (

parser.codenum) {

202 case 0:

case 1: G0_G1(

203 #

if IS_SCARA || defined(G0_FEEDRATE)

209 #if ENABLED(ARC_SUPPORT) && DISABLED(SCARA)

210 case 2:

case 3: G2_G3(

parser.codenum == 2);

break;

215 #if ENABLED(BEZIER_CURVE_SUPPORT)

219 #if ENABLED(FWRETRACT)

220 case 10: G10();

break;

221 case 11: G11();

break;

224 #if ENABLED(NOZZLE_CLEAN_FEATURE)

225 case 12: G12();

break;

228 #if ENABLED(CNC_WORKSPACE_PLANES)

229 case 17: G17();

break;

230 case 18: G18();

break;

231 case 19: G19();

break;

234 #if ENABLED(INCH_MODE_SUPPORT)

235 case 20: G20();

break;

236 case 21: G21();

break;

238 case 21:

NOOP;

break;

241 #if ENABLED(G26_MESH_VALIDATION)

242 case 26: G26();

break;

245 #if ENABLED(NOZZLE_PARK_FEATURE)

246 case 27: G27();

break;

249 case 28: G28(

false);

break;

253 #if ENABLED(G29_RETRY_AND_RECOVER)

259 #endif // HAS_LEVELING

262 case 30: G30();

break;

263 #if ENABLED(Z_PROBE_SLED)

264 case 31: G31();

break;

265 case 32: G32();

break;

269 #if ENABLED(DELTA_AUTO_CALIBRATION)

270 case 33: G33();

break;

273 #if ENABLED(Z_STEPPER_AUTO_ALIGN)

274 case 34: G34();

break;

277 #if ENABLED(G38_PROBE_TARGET)

289 #if ENABLED(CNC_COORDINATE_SYSTEMS)

290 case 53: G53();

break;

291 case 54: G54();

break;

292 case 55: G55();

break;

293 case 56: G56();

break;

294 case 57: G57();

break;

295 case 58: G58();

break;

296 case 59: G59();

break;

299 #if ENABLED(GCODE_MOTION_MODES)

300 case 80: G80();

break;

306 case 92: G92();

break;

309 case 42: G42();

break;

312 #if ENABLED(CALIBRATION_GCODE)

313 case 425: G425();

break;

316 #if ENABLED(DEBUG_GCODE_PARSER)

317 case 800:

parser.debug();

break;

320 default:

parser.unknown_command_error();

break;

324 case 'M':

switch (

parser.codenum) {

325 #if HAS_RESUME_CONTINUE

327 case 1: M0_M1();

break;

331 case 3: M3_M4(

false);

break;

332 case 4: M3_M4(

true );

break;

336 #if ENABLED(COOLANT_CONTROL)

337 #if ENABLED(COOLANT_MIST)

340 #if ENABLED(COOLANT_FLOOD)

346 #if ENABLED(EXTERNAL_CLOSED_LOOP_CONTROLLER)

347 case 12: M12();

break;

350 #if ENABLED(EXPECTED_PRINTER_CHECK)

351 case 16: M16();

break;

354 case 17: M17();

break;

356 #if ENABLED(SDSUPPORT)

357 case 20: M20();

break;

358 case 21: M21();

break;

359 case 22: M22();

break;

360 case 23: M23();

break;

361 case 24: M24();

break;

362 case 25: M25();

break;

363 case 26: M26();

break;

364 case 27: M27();

break;

365 case 28: M28();

break;

366 case 29: M29();

break;

367 case 30: M30();

break;

368 case 32: M32();

break;

370 #if ENABLED(LONG_FILENAME_HOST_SUPPORT)

371 case 33: M33();

break;

374 #if BOTH(SDCARD_SORT_ALPHA, SDSORT_GCODE)

375 case 34: M34();

break;

378 case 928: M928();

break;

381 case 31: M31();

break;

382 case 42: M42();

break;

384 #if ENABLED(PINS_DEBUGGING)

385 case 43: M43();

break;

388 #if ENABLED(Z_MIN_PROBE_REPEATABILITY_TEST)

389 case 48: M48();

break;

392 #if ENABLED(LCD_SET_PROGRESS_MANUALLY)

393 case 73: M73();

break;

396 #if ENABLED(M73_PRUSA)

397 case 73: M73_PE();

break;

400 case 75: M75();

break;

401 case 76: M76();

break;

402 case 77: M77();

break;

404 #if ENABLED(PRINTCOUNTER)

405 case 78: M78();

break;

408 #if ENABLED(M100_FREE_MEMORY_WATCHER)

409 case 100: M100();

break;

413 case 104: M104();

break;

414 case 109: M109();

break;

417 case 105: M105();

return;

420 case 106: M106();

break;

421 case 107: M107();

break;

424 case 110: M110();

break;

425 case 111: M111();

break;

427 #if DISABLED(EMERGENCY_PARSER)

428 case 108: M108();

break;

429 case 112: M112();

break;

430 case 410: M410();

break;

431 #if ENABLED(HOST_PROMPT_SUPPORT)

432 case 876: M876();

break;

435 case 108:

case 112:

case 410:

436 #if ENABLED(HOST_PROMPT_SUPPORT)

442 #if ENABLED(HOST_KEEPALIVE_FEATURE)

443 case 113: M113();

break;

447 case 140: M140();

break;

448 case 190: M190();

break;

451 #if HAS_HEATED_CHAMBER

452 case 141: M141();

break;

453 case 191: M191();

break;

456 #if ENABLED(AUTO_REPORT_TEMPERATURES) && HAS_TEMP_SENSOR

457 case 155: M155();

break;

460 #if ENABLED(PARK_HEAD_ON_PAUSE)

461 case 125: M125();

break;

464 #if ENABLED(BARICUDA)

467 case 126: M126();

break;

468 case 127: M127();

break;

473 case 128: M128();

break;

474 case 129: M129();

break;

479 case 80: M80();

break;

481 case 81: M81();

break;

483 case 82: M82();

break;

484 case 83: M83();

break;

485 case 18:

case 84: M18_M84();

break;

486 case 85: M85();

break;

487 case 86: M86();

break;

488 case 92: M92();

break;

489 case 114: M114();

break;

490 case 115: M115();

break;

491 case 117: M117();

break;

492 case 118: M118();

break;

493 case 119: M119();

break;

494 case 120: M120();

break;

495 case 121: M121();

break;

497 #if HOTENDS && HAS_LCD_MENU

498 case 145: M145();

break;

501 #if ENABLED(TEMPERATURE_UNITS_SUPPORT)

502 case 149: M149();

break;

506 case 150: M150();

break;

509 #if ENABLED(MIXING_EXTRUDER)

510 case 163: M163();

break;

511 case 164: M164();

break;

512 #if ENABLED(DIRECT_MIXING_IN_G1)

513 case 165: M165();

break;

515 #if ENABLED(GRADIENT_MIX)

516 case 166: M166();

break;

520 #if DISABLED(NO_VOLUMETRICS)

521 case 200: M200();

break;

524 case 201: M201();

break;

527 case 202: M202();

break;

530 case 203: M203();

break;

531 case 204: M204();

break;

532 case 205: M205();

break;

535 case 206: M206();

break;

539 case 665: M665();

break;

542 #if ANY(DELTA, X_DUAL_ENDSTOPS, Y_DUAL_ENDSTOPS, Z_DUAL_ENDSTOPS)

543 case 666: M666();

break;

546 #if ENABLED(FWRETRACT)

547 case 207: M207();

break;

548 case 208: M208();

break;

549 #if ENABLED(FWRETRACT_AUTORETRACT)

551 if (MIN_AUTORETRACT <= MAX_AUTORETRACT) M209();

556 #if HAS_SOFTWARE_ENDSTOPS

557 case 211: M211();

break;

561 case 217: M217();

break;

564 #if HAS_HOTEND_OFFSET

565 case 218: M218();

break;

568 case 220: M220();

break;

571 case 221: M221();

break;

574 case 226: M226();

break;

577 case 280: M280();

break;

578 #if ENABLED(EDITABLE_SERVO_ANGLES)

579 case 281: M281();

break;

583 #if ENABLED(BABYSTEPPING)

584 case 290: M290();

break;

588 case 300: M300();

break;

592 case 301: M301();

break;

595 #if ENABLED(PIDTEMPBED)

596 case 304: M304();

break;

599 #if ENABLED(PHOTO_GCODE)

600 case 240: M240();

break;

604 case 250: M250();

break;

607 #if ENABLED(EXPERIMENTAL_I2CBUS)

608 case 260: M260();

break;

609 case 261: M261();

break;

612 #if ENABLED(PREVENT_COLD_EXTRUSION)

613 case 302: M302();

break;

617 case 303: M303();

break;

620 #if HAS_USER_THERMISTORS

621 case 305: M305();

break;

624 #if ENABLED(MORGAN_SCARA)

625 case 360:

if (M360())

return;

break;

626 case 361:

if (M361())

return;

break;

627 case 362:

if (M362())

return;

break;

628 case 363:

if (M363())

return;

break;

629 case 364:

if (M364())

return;

break;

632 #if EITHER(EXT_SOLENOID, MANUAL_SOLENOID_CONTROL)

633 case 380: M380();

break;

634 case 381: M381();

break;

637 case 400: M400();

break;

640 case 401: M401();

break;

641 case 402: M402();

break;

644 #if ENABLED(PRUSA_MMU2)

645 case 403: M403();

break;

648 #if ENABLED(FILAMENT_WIDTH_SENSOR)

649 case 404: M404();

break;

650 case 405: M405();

break;

651 case 406: M406();

break;

652 case 407: M407();

break;

655 #if HAS_FILAMENT_SENSOR

656 case 412: M412();

break;

660 case 420: M420();

break;

664 case 421: M421();

break;

667 #if ENABLED(BACKLASH_GCODE)

668 case 425: M425();

break;

672 case 428: M428();

break;

675 case 500: M500();

break;

676 case 501: M501();

break;

677 case 502: M502();

break;

678 #if DISABLED(DISABLE_M503)

679 case 503: M503();

break;

681 #if ENABLED(EEPROM_SETTINGS)

682 case 504: M504();

break;

685 #if ENABLED(SDSUPPORT)

686 case 524: M524();

break;

689 #if ENABLED(SD_ABORT_ON_ENDSTOP_HIT)

690 case 540: M540();

break;

693 #if ENABLED(BAUD_RATE_GCODE)

694 case 575: M575();

break;

698 case 851: M851();

break;

701 #if ENABLED(SKEW_CORRECTION_GCODE)

702 case 852: M852();

break;

705 #if ENABLED(ADVANCED_PAUSE_FEATURE)

706 case 600: M600();

break;

707 case 603: M603();

break;

710 #if HAS_DUPLICATION_MODE

711 case 605: M605();

break;

714 #if ENABLED(FILAMENT_LOAD_UNLOAD_GCODES)

715 case 701: M701();

break;

716 case 702: M702();

break;

719 #if ENABLED(MAX7219_GCODE)

720 case 7219: M7219();

break;

723 #if ENABLED(GCODE_MACROS)

724 case 810:

case 811:

case 812:

case 813:

case 814:

725 case 815:

case 816:

case 817:

case 818:

case 819:

729 #if ENABLED(LIN_ADVANCE)

730 case 900: M900();

break;

733 #if HAS_DIGIPOTSS || HAS_MOTOR_CURRENT_PWM || EITHER(DIGIPOT_I2C, DAC_STEPPER_CURRENT)

734 case 907: M907();

break;

735 #if HAS_DIGIPOTSS || ENABLED(DAC_STEPPER_CURRENT)

736 case 908: M908();

break;

737 #if ENABLED(DAC_STEPPER_CURRENT)

738 case 909: M909();

break;

739 case 910: M910();

break;

745 case 122: M122();

break;

746 case 906: M906();

break;

748 case 569: M569();

break;

750 #if ENABLED(MONITOR_DRIVER_STATUS)

751 case 911: M911();

break;

752 case 912: M912();

break;

754 #if ENABLED(HYBRID_THRESHOLD)

755 case 913: M913();

break;

758 case 914: M914();

break;

762 #if HAS_DRIVER(L6470)

763 case 122: M122();

break;

764 case 906: M906();

break;

765 case 916: M916();

break;

766 case 917: M917();

break;

767 case 918: M918();

break;

771 case 350: M350();

break;

772 case 351: M351();

break;

776 case 355: M355();

break;

779 #if ENABLED(DEBUG_GCODE_PARSER)

780 case 800:

parser.debug();

break;

783 #if ENABLED(I2C_POSITION_ENCODERS)

784 case 860: M860();

break;

785 case 861: M861();

break;

786 case 862: M862();

break;

787 case 863: M863();

break;

788 case 864: M864();

break;

789 case 865: M865();

break;

790 case 866: M866();

break;

791 case 867: M867();

break;

792 case 868: M868();

break;

793 case 869: M869();

break;

796 #if ENABLED(MAGNETIC_PARKING_EXTRUDER)

797 case 951: M951();

break;

800 #if ENABLED(Z_STEPPER_AUTO_ALIGN)

801 case 422: M422();

break;

804 #if ENABLED(PLATFORM_M997_SUPPORT)

805 case 997: M997();

break;

808 case 999: M999();

break;

810 #if ENABLED(POWER_LOSS_RECOVERY)

811 case 413: M413();

break;

812 case 1000: M1000();

break;

815 default:

parser.unknown_command_error();

break;

819 case 'T': T(

parser.codenum);

break;

821 default:

parser.unknown_command_error();

◆ process_next_command()

| void GcodeSuite::process_next_command |

( |

| ) |

|

|

static |

Process a single command and dispatch it to its handler This is called from the main loop()

836 #if ENABLED(POWER_LOSS_RECOVERY)

843 #if ENABLED(M100_FREE_MEMORY_DUMPER)

850 parser.parse(current_command);

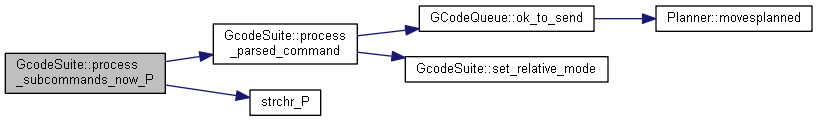

◆ process_subcommands_now_P()

| void GcodeSuite::process_subcommands_now_P |

( |

PGM_P |

pgcode | ) |

|

|

static |

Run a series of commands, bypassing the command queue to allow G-code "macros" to be called from within other G-code handlers.

860 char *

const saved_cmd =

parser.command_ptr;

863 const size_t len = delim ? delim - pgcode :

strlen_P(pgcode);

◆ process_subcommands_now()

| void GcodeSuite::process_subcommands_now |

( |

char * |

gcode | ) |

|

|

static |

876 char *

const saved_cmd =

parser.command_ptr;

878 char *

const delim = strchr(

gcode,

'\n');

879 if (delim) *delim =

'\0';

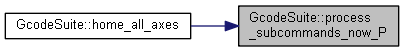

◆ home_all_axes()

| static void GcodeSuite::home_all_axes |

( |

| ) |

|

|

static |

◆ dwell()

Dwell waits immediately. It does not synchronize. Use M400 instead of G4

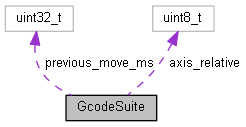

◆ axis_relative

◆ previous_move_ms

#define WITHIN(N, L, H)

Definition: macros.h:195

#define PENDING(NOW, SOON)

Definition: millis_t.h:28

#define SERIAL_CHAR(x)

Definition: serial.h:69

#define PORT_REDIRECT(p)

Definition: serial.h:66

u16_t len

Definition: pbuf.h:159

#define SERIAL_ECHO(x)

Definition: serial.h:70

static void process_subcommands_now_P(PGM_P pgcode)

Definition: gcode.cpp:859

static void process_parsed_command(const bool no_ok=false)

Definition: gcode.cpp:195

const char * strchr_P(const char *s, int c)

Definition: Marduino.h:57

static void ok_to_send()

Definition: queue.cpp:242

GCodeQueue queue

Definition: queue.cpp:28

#define IS_SD_PRINTING()

Definition: cardreader.h:295

Stopwatch print_job_timer

Definition: printcounter.cpp:63

#define SERIAL_ECHOPAIR(V...)

Definition: serial.h:114

#define PGM_P

Definition: pgmspace.h:30

T e

Definition: types.h:383

uint8_t i

Definition: screen_test_graph.c:72

static millis_t previous_move_ms

Definition: gcode.h:329

AxisEnum

Definition: types.h:36

xyze_pos_t destination

Definition: motion.cpp:110

uint32_t millis(void)

Definition: wiring_time.c:29

static uint8_t queue_index_r

Queue index of the active command.

Definition: power_loss_recovery.h:113

PrintJobRecovery recovery

#define SERIAL_ECHO_START()

Definition: serial.h:179

#define SERIAL_ECHOLN(x)

Definition: serial.h:72

#define KEEPALIVE_STATE(N)

Definition: gcode.h:365

#define strlen_P(s)

Definition: pgmspace.h:61

#define MSG_INVALID_E_STEPPER

Definition: language.h:168

static char command_buffer[BUFSIZE][MAX_CMD_SIZE]

Definition: queue.h:54

#define PSTR(str)

Definition: pgmspace.h:31

xyze_pos_t current_position

Definition: motion.cpp:102

static constexpr xyze_bool_t ar_init

Definition: gcode.cpp:53

#define LOGICAL_TO_NATIVE(POS, AXIS)

Definition: motion.h:270

static uint8_t index_r

Definition: queue.h:51

GcodeSuite gcode

Definition: gcode.cpp:29

static bool axis_is_relative(const AxisEnum a)

Definition: gcode.h:294

T x

Definition: types.h:383

feedRate_t feedrate_mm_s

Definition: motion.cpp:138

#define SERIAL_ECHOLNPAIR(V...)

Definition: serial.h:144

list a

Definition: createSpeedLookupTable.py:29

static void set_relative_mode(const bool rel)

Definition: gcode.h:301

#define _BV(bit)

Definition: wiring_constants.h:99

#define E_STEPPERS

Definition: Conditionals_LCD.h:429

#define IS_SCARA

Definition: Conditionals_LCD.h:544

#define CBI(A, B)

Definition: macros.h:89

static void save(const bool force=false, const bool save_queue=true)

#define EXTRUDERS

Definition: Configuration_A3ides_2209_MINI.h:148

#define DEBUGGING(F)

Definition: serial.h:47

#define strncpy_P(a, b, n)

Definition: pgmspace.h:66

#define TEST(n, b)

Definition: macros.h:81

static uint8_t axis_relative

Definition: gcode.h:292

#define NOOP

Definition: macros.h:258

#define SBI(A, B)

Definition: macros.h:85

const xyze_char_t axis_codes

Definition: types.h:486

#define SERIAL_ECHOLNPGM(S)

Definition: serial.h:174

#define LOOP_XYZE(VAR)

Definition: types.h:61

void idle()

Definition: Marlin.cpp:629

#define MSG_E_STEPPER_NOT_SPECIFIED

Definition: language.h:169

static bool enabled

Definition: power_loss_recovery.h:138

#define MSG_INVALID_EXTRUDER

Definition: language.h:167

constexpr uint8_t active_extruder

Definition: motion.h:107

#define ENABLED(V...)

Definition: macros.h:177

T y

Definition: types.h:383

parser

Definition: createSpeedLookupTable.py:14